-

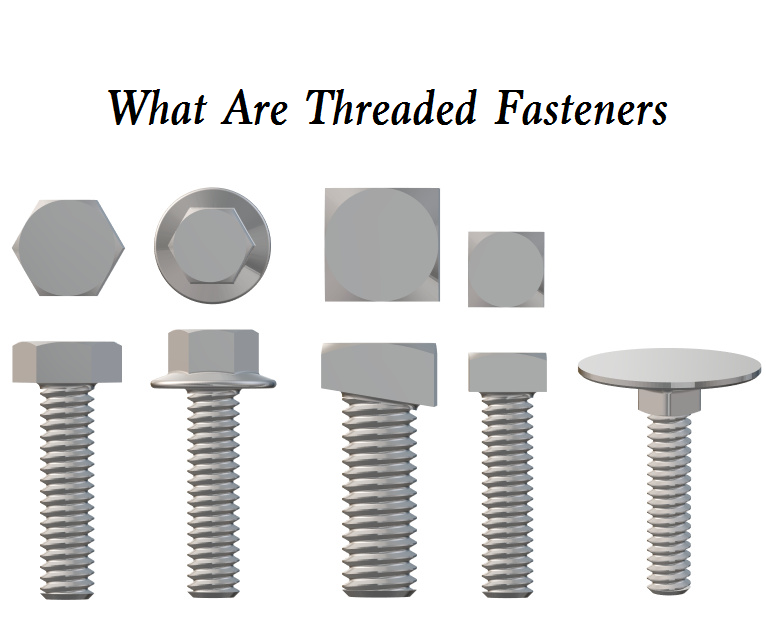

Threaded fasteners are fundamental mechanical parts designed to firmly connect two or more components using matching threads. They are indispensable across countless industries as they provide reliable joints that hold structures and machinery together. In this blog, let’s learn everything about threaded fasteners, covering the definition, working principle, types, advantages, uses, materials, and comparison with non-threaded fasteners. What Are Threaded Fasteners? Threaded fasteners are essential hardware components that create secure joints between objects by utilizin......

2025.11.27Published by @LJCRead More -

So, you’ve got your CNC machine humming in the garage, or maybe you’re about to pull the trigger on one. You’re ready to turn digital dreams into sawdust-covered reality. But there’s a catch: your CNC machine needs instructions. That’s where CNC software comes in. In this guide, you’ll learn what CNC software actually does, why it matters, and which CNC programs are the best for 2026. What is CNC Software? CNC software is the digital tool that tells computer-controlled machines—like mills, routers, lathes, and plasma cutters—exactly how to move, c......

2025.11.17Published by @WCYRead More -

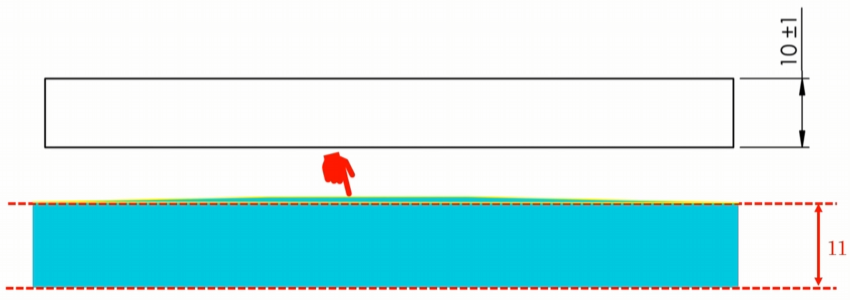

Geometric Dimensioning and Tolerancing (GD&T) Rule #1 and Rule #2 are two key concepts that form the foundation for geometric control in engineering drawings. These rules define how features are evaluated for form and size, influencing the quality and function of manufactured parts. Grasping their differences, applications, and interactions can help ensure reliable assembly and minimize design errors. Here, the envelope principle, typical scenarios, strengths, and drawbacks of both rules will be discussed with practical examples. What is GD&T Rule 1? GD&T Rule 1, also ......

2025.11.17Published by YLRead More -

Among various steel materials for CNC machining, S45C is a widely used carbon steel with good properties and machinability. This guide explores everything you should know about S45C steel, including its equivalent grades, chemical composition, mechanical and physical properties, corrosion resistance, and heat resistance. Additionally, we delve into its weldability, machinability, and heat treatment processes. We also provide detailed comparisons between S45C steel and other grades like SS400 and S50C What Is S45C Material? S45C is a medium-carbon steel grade under the JIS G4051 standard,......

2025.10.29Published by @LJCRead More -

Cutting metal and other materials is a fundamental part of fabrication, construction, and manufacturing — but not all cutting tools work the same way. Among the most widely used methods today are plasma cutters, laser cutters, and torches, each with its own strengths, limitations, and ideal applications. In this article, we’ll explain what each tool is, how it works, and highlight the key differences between them. What is Plasma Cutter? A plasma cutter is a tool used to cut through electrically conductive materials such as steel, aluminum, brass, copper, and stainless steel using ......

2025.10.29Published by @WCYRead More -

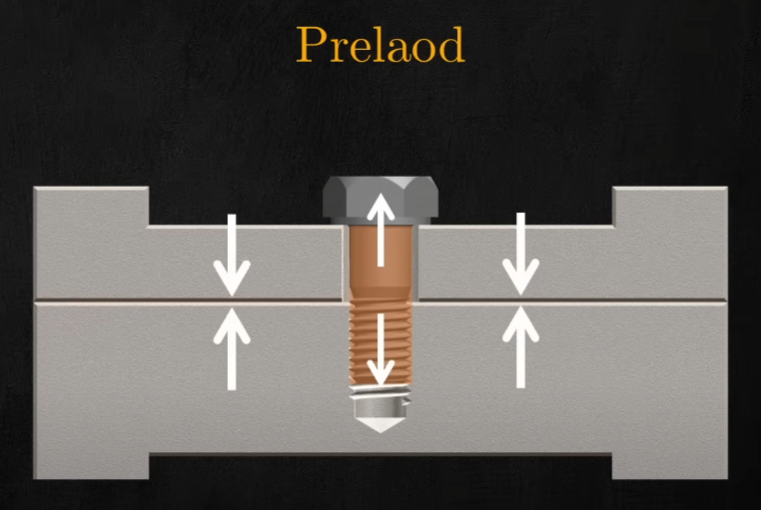

In mechanical design, making the right choices for bolt sizing, selection, and application is key for both safety and efficiency. Often, experienced engineers rely on thumb rules and practical experience for everyday applications. However, in situations where safety or dynamic loads are involved, precise bolt sizing calculations become necessary. This article provides a comprehensive overview of bolt preload, tension and shear load, bolt grades, and the calculation methods for bolt sizing, as well as practical thumb rules used in industry. When to Calculate Bolt Size Most design e......

2025.10.17Published by YLRead More -

When building or fixing things with screws and bolts, it’s very important to make the correct holes for the screws or bolts to fit properly. Clearance holes help screws and bolts fit through parts easily and securely without damaging the materials. Using the right type and size of hole ensures that the parts are tightly joined, safe, and strong. In this article, we’ll explain what clearance holes are, how they differ from other types of holes like tapped holes and pilot holes, and how to calculate and find the right diameter using formulas and metric/imperial bolt clearance hole charts.......

2025.9.26Published by @LJCRead More -

When it comes to versatile metals, brass, copper, and bronze are three of the most widely used materials in industries ranging from construction and plumbing to art, electrical engineering, and marine applications. In this guide, we’ll break down the key differences between brass, copper, and bronze, exploring how their compositions, mechanical properties, applications, and costs influence where and why they are used. What is Brass? Brass is a versatile metal alloy primarily made from copper and zinc, with the proportions of each element varying to create different properties such......

2025.9.19Published by @WCYRead More