Peck drilling, known as a notable machining process of making narrow but very deep holes in solid materials, usually metals. This technique moves the cutter downward by small, measurable amounts so that it clears away chips and remains cool. Today we will talk about what is perk drilling meaning, its uses cirlcles, g codes, and the differences between G83 and G73.

What is Peck Drilling?

Peck drilling breaks down the entire depth of a hole into a series of manageable steps or pecks. Each advance cuts into the workpiece, retracts to clear swarf and then repeats until the final depth is achieved. Such intermittent approach regulates temperature while prolonging tool life and greatly enhancing surface finish thus making it ideal for jobs involving tough alloys or thick sections. Industries desiring accuracy and endurance always resort to it when deep diameter-to-depth ratios are required.

Applications of Peck Drilling

- Aerospace: For making precise drilled holes in aircraft components and structures.

- Automotive: Used in engine block machining and chassis fabrication.

- Oil and Gas: Used in drilling equipment and maintenance of pipelines.

- Manufacturing: Used for producing parts for machinery and tools.

What are the Advantages of Peck Drilling?

- Peck drilling reduces the risk of drill bit breakage in deep holes by improving chip removal and cooling. (1st paragraph)

- Incremental drilling prevents chips from being packed into the flutes hence minimizing clogging and resulting to better cutting efficiency . (2nd paragraph).

- Through peck drilling, coolant is able to reach the drill tip effectively thus maintaining optimal cutting temperatures that guarantee longer tool life. (3rd paragraph)

- The above method improves precision as well as surface finish – particularly for deep, narrow holes – which ultimately leads to better part quality at large.

What are the Disadvantages of Peck Drilling?

The flip side is that multiple engagements stretch the cycle time, sometimes doubling it when compared to a single-pass method. Setting up the CNC program is less intuitive, since each step depth must be dialed in precisely or the sequence falters. Finally, overall throughput takes a hit if operators have to run at conservatively slow feeds just to accommodate that initial depth and keep the tool intact.

What is the Peck Drilling Cycle Code?

CNC programming has a peck drilling cycle code. It is used to make the drilling of deep holes in increments of pecks making it easier. The drill bit gradually moves down into the material which helps in chip removal and cooling process, thus reducing tool wear and breakage risks. Some popular codes include G83 for deep hole drilling with full retraction after each peck and G73 for shallow hole drilling that employs a shorter retraction distance. By applying these codes, operators can achieve enhanced accuracy and effectiveness in different machining processes.

What is Peck Drilling Cycle?

The peck drilling cycle breaks a deep hole into manageable increments instead of plunging to full depth in one go. Each pass, or peck, advances the bit slightly and then retracts to clear chips.

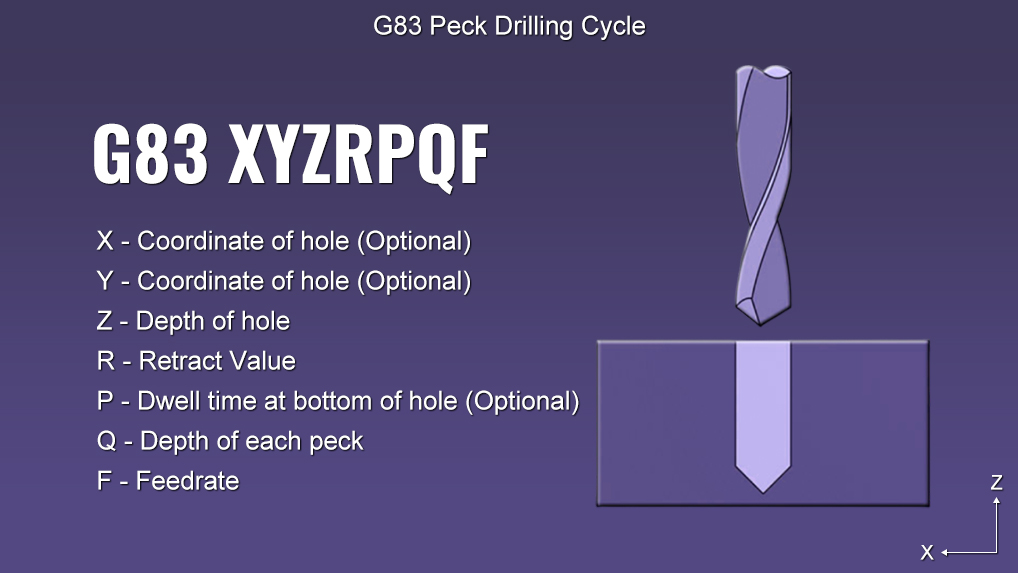

G83 Peck Drilling Cycle

The G83 command stitches those increments into a CNC program, telling the control to descend, retract, and repeat. A defined retract height (R value) keeps the tool clear for swarf evacuation.

Syntax: G83 X Y Z R P Q F

X: Optional coordinate of the hole

Y: Optional coordinate of the hole

Z: Final depth of the hole

R: Retract value (height to which the drill retracts)

P: Dwell time at the bottom of the hole

Q: Depth of each peck

F: Feed rate

G83 Peck Drilling Cycle Example

A wire-frame example sharpens the point. Picture a 1-inch pocket at Cartesian X2.0 Y3.0, carved back to Z-1.0 and hoisted to an R of 0.2. P pauses for one-half second, Q peels off 0.25 at a 5-inch pace.

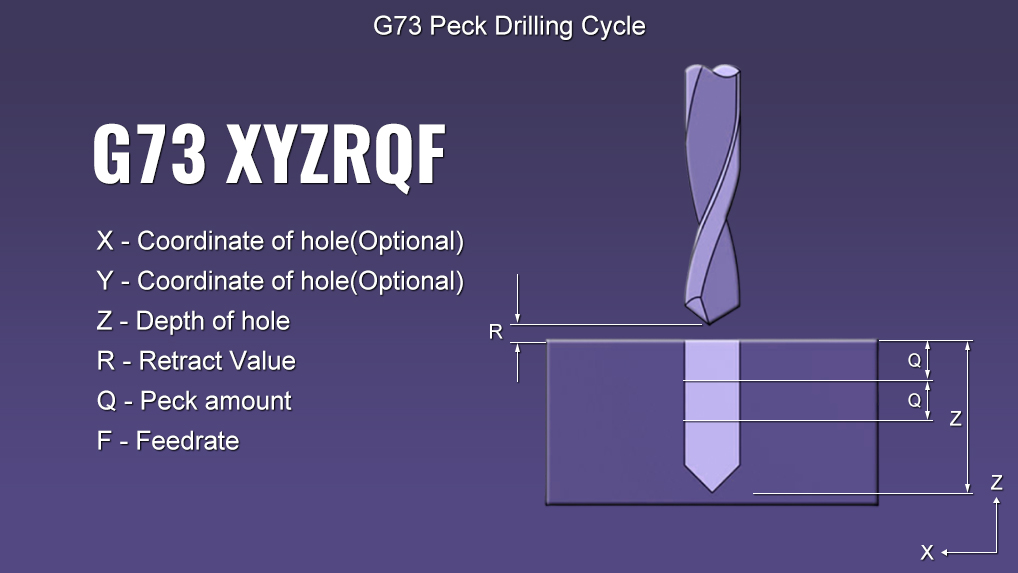

G73 Peck Drilling Cycle

The G73 Peck Drilling Cycle is another CNC command used for efficient drilling, particularly for shallow and medium-depth holes. Unlike G83, the G73 cycle does not fully retract the drill to a clearance height after each peck. Instead, it retracts to a set distance within the hole, acting as a chip breaker. This method is faster, especially when drilling multiple holes, as it minimizes the time spent retracting the drill completely. Ideal for long drills that may experience vibration, keeping the drill bit inside the hole reduces instability.

Syntax: G73 X Y Z R Q F

X: Optional coordinate of the hole

Y: Optional coordinate of the hole

Z: Final depth of the hole

R: Retract value (set distance within the hole)

Q: Depth of each peck

F: Feed rate

G73 Peck Drilling Cycle Example

You need to drill a 0.75-inch deep hole at coordinates (X=4.0, Y=2.5) with a retract distance of 0.1 inches within the hole, each peck being 0.2 inches deep. The feed rate is set at 4 inches per minute.

Differences Between G83 & G73 Peck Drilling Cycle

G73 offers a rigid, high-speed solution for drilling shallow pockets; its stepped motion fragments the chip quickly and keeps the spindle moving. G83, by contrast, withdraws the tool completely with each cycle, making it the standard for deep holes where effective chip clearance and active coolant flow are non-negotiable.

| Feature | G73 Peck Drilling Cycle | G83 Peck Drilling Cycle |

|---|---|---|

| Purpose | Short peck drilling for shallow holes | Deep hole drilling with full retract |

| Retract Behavior | Short retract within the hole | Full retract above the surface |

| Chip Management | Primarily for chip breaking | Effective for clearing chips from deep holes |

| Cycle Speed | Generally faster due to less retract time | Slower due to full retraction |

| Recommended Depth | Shallow to medium depths | Typically for deeper holes |

| Usage | Often used with long drills prone to vibration | Used when drilling deep holes requiring precision |

| Dwell Time | Typically no dwell time | Can include dwell time at the bottom |