-

In this guide, we explain the Column and Knee Type Milling Machine by discussing its construction and work principle in parts and diagram, as well as the main types of this horizontal milling machine. Then you will know what the Column and Knee Type Milling Machine is and how it works in CNC machining! What is Column and Knee Type Milling Machine? Column and Knee Type Milling Machine is a type of milling machine where the table is mounted on the knee casting, which is in turn mounted on the vertical slide of a main column. The knee is vertically adjustable on the column so tha......

2025.6.10Published by YLRead More -

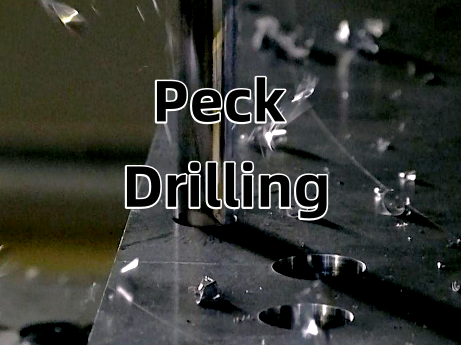

Peck drilling, known as a notable machining process of making narrow but very deep holes in solid materials, usually metals. This technique moves the cutter downward by small, measurable amounts so that it clears away chips and remains cool. Today we will talk about what is perk drilling meaning, its uses cirlcles, g codes, and the differences between G83 and G73. What is Peck Drilling? Peck drilling breaks down the entire depth of a hole into a series of manageable steps or pecks. Each advance cuts into the workpiece, retracts to clear swarf and then repeats until the fin......

2025.6.10Published by @WCYRead More -

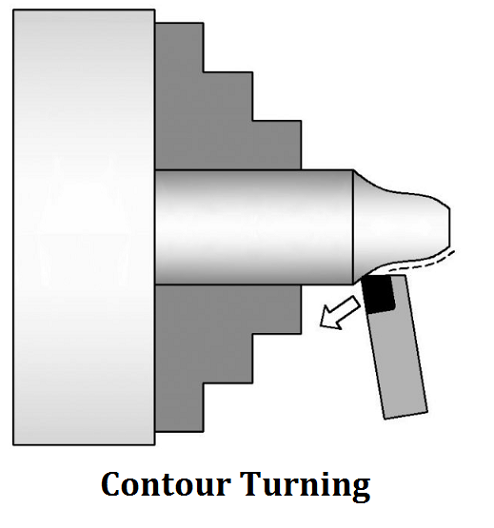

Contour turning is a special turning process for the machining of non-cylindrical workpieces. Instead of the one or two-dimensionally shaped turned pieces obtained by conventional turning systems, which are generally limited to the production of cylindrical or conical shapes, the turning process allows convexed curves, angles, and complex contours. The following guide is to provide an overview of contour turning, mainly covering what it is, how it works, the basics, what you need, where it is used, its pros and cons, and a comparison with other turning methods in each aspect. What Is Con......

2025.5.28Published by @LJCRead More -

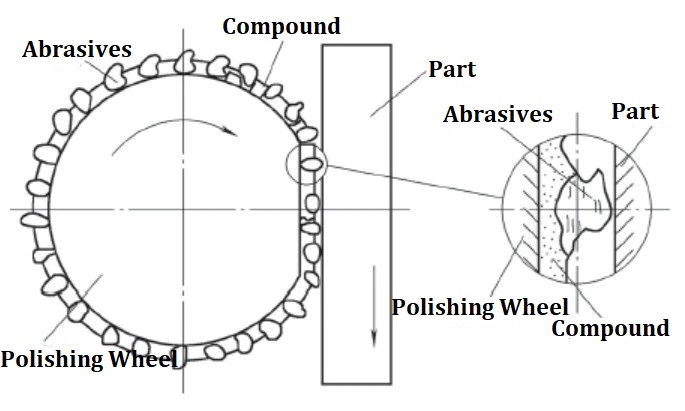

Today, we are going to talk about one of the important finishing processes in CNC machining – Polishing aka Buffing, going over the principles and methods of polishing, as well as the operating necessary points you must know in common polishing processes. Through the correct application of polishing wheels, polishing agents, abrasive particle size, and buffing speed, the surface of the parts can be made as bright as a mirror. What is Polishing in CNC Machining? Polishing is a process of buffing parts in mechanical processing, which can make the surface of the parts as bright......

2025.5.27Published by YLRead More -

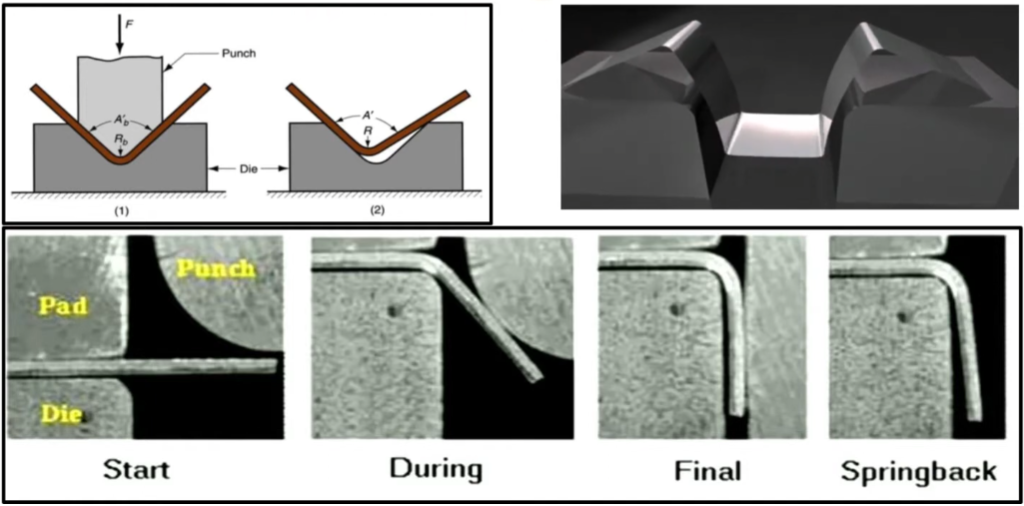

Sheet metal forming is a key manufacturing process, where forming accuracy directly impacts product quality and performance. One common issue encountered during bending and forming is springback, where the metal partially returns to its original shape after the external force is removed. This elastic recovery causes deviations from the intended dimensions and can complicate assembly. As a result, springback remains one of the main challenges in sheet metal fabrication. This article examines the causes of springback and presents practical strategies for minimizing its effects. By conside......

2025.4.23Published by YLRead More -

Die casting is a highly precise manufacturing process that transforms raw materials into intricate, durable metal components. In today’s competitive industrial landscape, the quality control process is not just a procedural checkpoint but the backbone of efficiency, safety, and consistency throughout production. In a die casting workshop, meticulous oversight—from the initial melting of the alloy to the final production inspection—is crucial in preventing defects, reducing waste, and assuring that each piece meets or exceeds stringent quality standards. This article delves into th......

2025.4.17Published by @WCYRead More -

Staying competitive requires innovative approaches to product development, and this is where rapid prototyping combined with CNC machining becomes indispensable. This combination accelerates the creation of custom robotic components, ensuring they meet the highest standards of quality and performance. In this guide, we will explore the importance of rapid prototyping, robot prototypes, the process of CNC machining for rapid prototyping, and how to select materials and parameters for robot manufacturing. The Importance of Rapid Prototyping in Robotic Manufacturing Speed and Co......

2025.2.21Published by @LJCRead More -

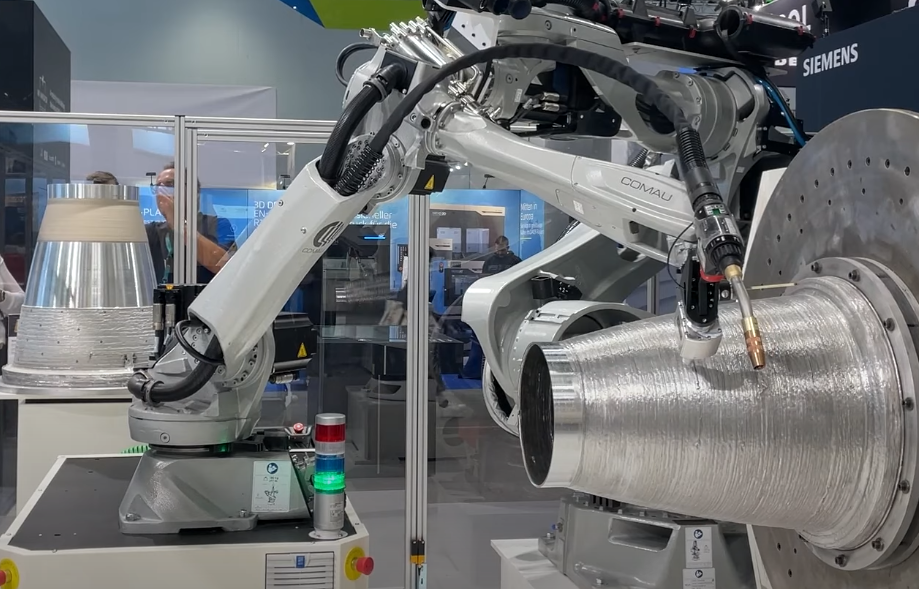

The evolution of manufacturing is driving the need for more efficient, precise, and adaptable production methods. Hybrid manufacturing, which combines CNC machining with additive manufacturing (AM), is emerging as a key approach for producing next-generation robotic components. This method integrates the accuracy of subtractive machining with the flexibility of additive techniques, enabling engineers to design and manufacture parts that are lighter, stronger, and more complex. According to Wohlers Report 2023, the hybrid manufacturing market is growing at an annual rate of 22%, with ......

2025.2.21Published by YLRead More