In this guide, we explain the Column and Knee Type Milling Machine by discussing its construction and work principle in parts and diagram, as well as the main types of this horizontal milling machine. Then you will know what the Column and Knee Type Milling Machine is and how it works in CNC machining!

What is Column and Knee Type Milling Machine?

Column and Knee Type Milling Machine is a type of milling machine where the table is mounted on the knee casting, which is in turn mounted on the vertical slide of a main column. The knee is vertically adjustable on the column so that the table can move up and down to accommodate workpieces of various heights.

Column and Knee Type Milling Machine Construction (Diagram, Parts & Working)

So how does the Column and Knee Type Milling Machine work? Let us tell you the answer by interpreting its Diagram and each component in its structure:

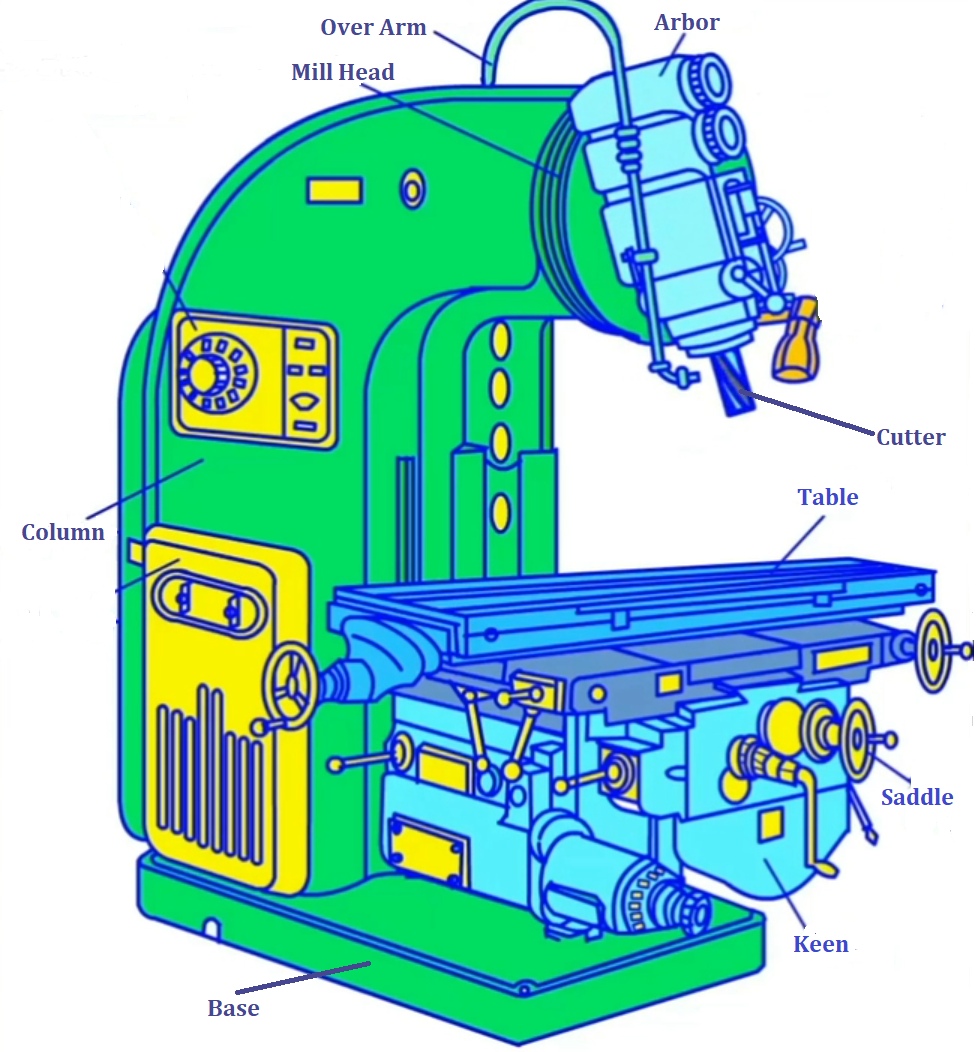

Column and Knee Type Milling Machine Diagram

Column and Knee Type Milling Machine Parts & Work

Now we explain each part of the Column & Knee Type Milling Machine in detail, and what role they play:

Base – The base is the foundation member for all other parts. It carries the column at one end and acts as a load taking member for all other parts of the machine and a reservoir for the coolant.

Column – The column is the main supporting member mounted vertically on the base. It is box-shaped, heavily ribbed inside, and houses all the driving mechanisms for the spindle and table feed. The front vertical face of the column is accurately machined and provided with guideways for supporting the knee.

Knee – The knee is a rigid iron casting that slides up and down on the vertical ways of the column face. It is adjusted by the elevating screw jack mounted on the base, which also supports the knee.

Elevating Screw Jack – The elevating screw jack is mounted on the base and used to adjust the height of the knee, allowing vertical movement of the table.

Saddle – The saddle is placed on top of the knee and slides on guideways set at exactly 90 degrees to the column face. The top of the saddle provides a guideway for the table.

Table – The table rests on the ways of the saddle and travels longitudinally. The top of the table is accurately finished and T-slots are provided for clamping the workpiece and other fixtures.

Overhanging Arm – The overhanging arm is mounted on top of the column and extends beyond the column face. It serves as a bearing support for the other end of the arbor. To support the projecting arbor, it can slide horizontally, forward and backward and adjusted at required position.

Front Brace – The front brace is an extra support fitted between the knee and the overhanging arm to provide additional rigidity to the arbor and knee.

Spindle – The spindle is situated in the upper part of the column and receives power from the motor through belts and gears.

Arbor – The arbor acts as an extension of the machine spindle on which milling cutters are securely mounted and rotated. Arbors have taper shanks for proper alignment with the machine spindle, which has a taper hole at the nose. A draw bolt is used to lock the arbor and the whole assembly with the spindle.

Types of Column and Knee Type Milling Machine

There are four types of column milling machines that are likely to be found in the machine shop:

Ram Vertical Milling Machine

Ram Vertical Milling Machine is often referred to as a Bridgeport style, this type has a lot of versatility. It has a ram on the end of the column that will extend and retract towards and away from the column and also swivel around the column. It has a milling head on the end of that ram which will tilt towards the column or away from the column and also will tilt around the column. It also has an “e” on the bottom which will be raised and lowered, and this will be common to all of the four types of milling machines we talke about here. On top of the knee is a saddle and then the table. The table will move in the X position left or right; it will also move in and out (traverse). The spindle will move up and down as well as the knee moving up and down. On the end of the spindle on this particular model there will be an R8 style milling machine taper which goes into the spindle. The spindle will extend and retract much like a drill press. On the top of the milling head there is a speed selection lever which will allow you to dial the speed you want once the spindle is turning.

Standard Vertical Milling Machine

Standard Vertical Milling Machine is a standard vertical milling machine and although it is similar to the ram type vertical milling machine, this one is more suitable to heavier types of work. This one likely will have power feeds on most of the axes, if not all of the axes, and rapids on them, whereas the ram type vertical not likely will unless it has been added to it. The difference with this one is it does not have a ram on top of the column. Other than that, if you have a look at the spindle, it takes a standard milling machine taper typically, and the arbor goes in it. In other words, the arbor has a cutter on the end of it and will be quite short in length.

Plain Style Horizontal Milling Machine

Plain Style Horizontal Milling Machine is a horizontal milling machine and this particular model has the standard milling machine taper. It has all the features of the vertical milling machine we just had a look at, but instead of having a ram on top of the column, it has what is called an overarm and then it has an overarm support. You can see it on the back of the column. When the overarm is extended in front of the column towards the table, the overarm support would then go in the position on the end of that ram. Then we would put an arbor in the spindle and likely take either a B style arbor or an A style arbor, although it could take a C style arbor. The A and B style arbors are quite long and are supported both in the spindle and by the overarm support on the other end with the cutter being in the middle. This one is very handy for doing helical milling on gears and things like that. You can see the shroud at the far end of the table there, which can be geared to the lead screw of the milling machine table in order to advance the work being held in a dividing head in order to cut a helical gear.

Universal Style Horizontal Milling Machine

What makes Universal Style Horizontal Milling Machine either a plain style milling machine or universal style horizontal milling machine is the table. If the table swivels, it is a universal horizontal milling machine rather than a plain style horizontal milling machine. Having a closer look between the saddle and the table of the horizontal milling machine, you can see that there is a protractor on the front of this one. In other words, the table will swivel off of being perpendicular to the spindle, right or left. This makes it a universal horizontal milling machine. This is also a horizontal milling machine. Please notice that it has a vertical milling head attachment bolted to the front of the column in order to mill in the vertical position. Also, note that the overarm is pushed back out of the way so the vertical milling head attachment can be bolted to the front of the column. This is a close-up of the vertical milling head attachment. This one will have a standard milling machine taper in it. It also will articulate in a couple of different positions around the column. You can see the scale on the side.

What is Column and knee type Milling Machine Used For?

Column and Knee Type Milling Machines are widely used in metalworking and manufacturing for various machining operations. Here’s what they are primarily used for:

- Machining Flat Surfaces – Great for creating flat surfaces on workpieces, such as faces of metal blocks.

- Slotting and Grooving – Used to cut slots, grooves, and keyways in mechanical parts

- Gear Cutting – Can be used with attachments for cutting gears.

- Drilling and Boring – Performs drilling and boring operations when fitted with appropriate tools.

- Shaping Complex Surfaces – Allows machining of complex shapes and contours by controlling the table movement.

- General Purpose Milling – Suitable for a wide range of milling tasks on medium to large workpieces.