Today, we are going to talk about one of the important finishing processes in CNC machining – Polishing aka Buffing, going over the principles and methods of polishing, as well as the operating necessary points you must know in common polishing processes. Through the correct application of polishing wheels, polishing agents, abrasive particle size, and buffing speed, the surface of the parts can be made as bright as a mirror.

What is Polishing in CNC Machining?

Polishing is a process of buffing parts in mechanical processing, which can make the surface of the parts as bright as a mirror. All kinds of molds, decorative parts, and parts with high appearance requirements must be polished before electroplating. Polishing and buffing processing is divided into three stages: rough polishing, medium polishing, and fine polishing. When rough polishing, a polishing wheel with pre bonded abrasive is generally used. Due to the strong adhesion of the abrasive, the polishing process is similar to the finishing process using grinding wheels, sand belts, and sanding cloth impellers; During medium and precision polishing, first apply the polishing agent onto a softer polishing wheel, and then press the workpiece onto a high-speed rotating polishing wheel for polishing processing.

CNC Polishing & Buffing Process Principle & Types

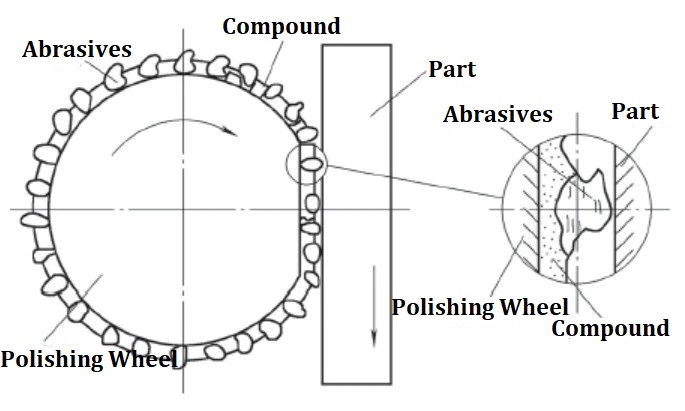

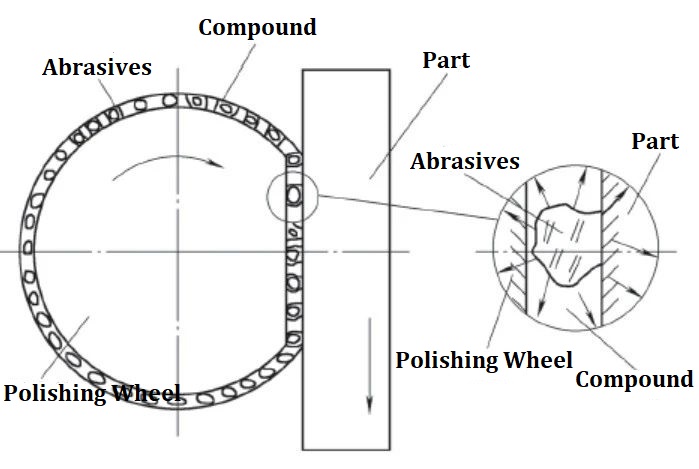

The basic principle of polishing is to use an elastic polishing wheel bonded or coated with abrasive to perform soft grinding on the workpiece under high-speed rotation conditions. Polishing can be divided into the following three types.

1. Fixed abrasive polishing – Fixed abrasive polishing uses fixed abrasives bonded with glue for polishing. Since the abrasives and the soft polishing wheel surface are firmly bonded, the cutting force is large, and its principle is similar to grinding. When polishing, the rotation direction of the polishing wheel is the same as the feed direction of the workpiece, and a very shiny surface can be obtained. If the directions are opposite, the abrasives have a large cutting force at the contact point between the polishing wheel and the workpiece, causing scratches on the workpiece surface and making it rough.

2. Adhesive abrasive polishing – Polishing is performed using an abrasive polishing wheel that is adhered to the grease. Under the action of force, the abrasive can slowly roll in the grease, so that all the cutting edges of the abrasive have the opportunity to participate in the work, so that the polishing wheel can maintain long-term working ability. At the same time, under the action of friction heat and processing pressure, the fatty acid and other media in the polishing agent react chemically with the metal surface to generate easily removable compounds, thereby accelerating the polishing efficiency.

3. Liquid polishing – Polishing wheels are generally made of uniform and degreased wood or special fine felt. Both materials are highly impregnable and can be impregnated with a large amount of polishing liquid for processing during the polishing process. The principle is to complete the polishing process through four stages, namely free polishing stage, inlay polishing stage, saturated passivation polishing stage and “shell film” polishing stage. When using a fine felt polishing wheel, the felt is soft and uniform, with greater elasticity and impregnation, so the entire polishing time is shorter, with only three polishing stages: inlay, saturated passivation and “shell film”.

CNC Polishing Wheel Materials

Relative soft materials like cotton, linen, felt, leather, carton paper, soft wood, and wool fabrics are used rather often for polishing wheels. Rough polishing to increase job efficiency calls for a strong polishing force. One might employ rather hard polishing wheel materials including canvas, felt, carton paper, cork, leather and linen. Selected materials for medium and fine polishing are cotton cloth, felt, and other polishing wheel materials with good softness and good retention with polishing agents. Processing the polishing wheel material comes before manufacturing. The procedure aims to increase stiffness, polishing ability, fiber strength, service life, softness, “profile” ability, retention, lubricity,y and flame resistance of polishing agents. The techniques of processing consist of bleaching, sizing, wax treatment, resin treatment, and chemical treatment. Changing the stitching technique and mesh spacing of the polishing wheel helps one to change the elasticity and rigidity of the wheel. Manufactured and applied easily, the spiral stitching technique is extensively employed. There are other radial stitching techniques, chessboard and concentric circle patterns. The elasticity of the polishing wheel will be great if the stitching technique is the same and if the stitching interval is big; otherwise, the elasticity will be low, and the stiffness will be great.

CNC Polishing & Buffing Compounds

Polishing Compounds are a uniform mixture of powdered polishing material, grease, and other appropriate components. According to its state at room temperature, it can be divided into solid polishing compounds and liquid polishing compounds. Solid polishing compound can be divided into two types according to the composition or properties of the medium: greasy type and non-greasy type. Liquid polishing compound can be divided into three types according to the composition or properties of the medium: emulsion type, liquid grease type, and non-grease type. However, the most commonly used is the solid polishing compound.

Solid oily polishing compounds include:

- Seiza polishing compound (molten aluminum oxide), which is used for rough polishing of carbon steel, stainless steel, and non-ferrous metals;

- Corundum compound (molten aluminum oxide, corundum), which is used for rough and medium polishing of carbon steel and stainless steel;

- Yellow polishing compound (plate-shaped diatomite), which is used for medium polishing of iron, brass, aluminum, and zinc;

- Rod-shaped iron oxide, which is used for medium and fine polishing of copper, brass, aluminum, and copper-plated surfaces;

- White polishing compound (roasted dolomite), which is used for fine polishing of copper, brass, aluminum, copper-plated surfaces, and nickel-plated surfaces;

- Green polishing compound (chromium oxide), which is used for fine polishing of stainless steel, brass, and chrome-plated surfaces;

- Red polishing compound (refined iron oxide), which is used for fine polishing of gold, silver, and platinum;

- Plastic polishing compound (microcrystalline anhydrous carbonic acid), which is used for fine polishing of plastic, leather, and ivory.

Liquid polishing agents generally use a liquid mixed with chromium oxide and emulsion.

Abrasives for CNC Polishing and Buffing

The particle size of the abrasive in the polishing agent has a direct impact on the surface roughness value and polishing efficiency of the workpiece after polishing. If the abrasive particle size is coarse, the surface roughness value of the workpiece is large, and the processing efficiency is high; if the abrasive particle size is fine, the surface roughness value of the workpiece is small, but the processing efficiency is low. When the surface roughness value Ra is required to be 1.6-3.2μm, the particle size is F46-F60; when Ra is required to be 0.4-0.8μm, the particle size is F100-F180; when Ra is required to be 0.1-0.2μm, the particle size is F240-W28; when Ra is required to be 0.025-0.05μm, the particle size is W20-W5; when Ra≤0.012μm, the particle size is

CNC Polishing (Buffing) Speed and Pressure

1. Circumferential speed of polishing wheel – During polishing, the higher the circumferential speed under certain pressure conditions, the smaller the amount of abrasive cutting, which is conducive to reducing the surface roughness value of the workpiece and improving the polishing efficiency accordingly. When polishing harder materials such as steel, cast iron, nickel and chromium, the speed of the polishing wheel is 30-35m/s; when polishing copper, copper alloy and silver, the speed of the polishing wheel is 20-30m/s; when polishing soft materials such as aluminum, aluminum alloy, zinc and tin, the speed of the polishing wheel is 18-25m/s. In actual work, when selecting the polishing wheel speed, it is necessary to flexibly grasp it according to the specific situation to achieve the purpose of safety, efficiency and quality.

2. Pressure during polishing – The pressure of the workpiece against the polishing wheel during polishing is closely related to the polishing efficiency and the surface quality of the workpiece. During rough polishing, the pressure is relatively large to improve work efficiency; during fine polishing, a smaller pressure is used to improve the surface quality of the workpiece. Generally, the pressure during rough polishing is 10-30MPa, and the pressure during fine polishing is 5-10MPa.

Other Polishing and Buffing Processes in CNC Machining

1. Sandpaper (cloth) polishing – This method is simple and flexible to operate and is a traditional process method. It can be done manually on a lathe or grinder to further reduce the surface roughness value of the workpiece, without the need for other equipment. However, the abrasive grain size of the sandpaper must be reasonably selected according to the surface roughness value requirements of the workpiece. For example, when the surface roughness value Ra=0.1~0.8μm is required, the abrasive grain size of the sandpaper is F150~F240. For the polishing of inner holes and profiles (grooves), sandpaper impeller polishing is now widely used. This impeller is made of resin to bond abrasive grains to sandpaper. The sandpaper on the impeller is distributed in an involute shape, is very soft, has high density and is elastic. When used, it can be installed on an electric or pneumatic tool. Sandpaper impellers of different diameters and grain sizes can be selected according to the surface requirements of the workpiece, which is very convenient.

2. Liquid polishing – A mixed suspended sand liquid carrying abrasive and liquid is sprayed at high speed onto the workpiece surface through a nozzle using compressed air for finishing. This polishing method can generally quickly obtain Ra=0.05~0.1μm based on the surface roughness value Ra=0.2μm. It is mainly used for surfaces that are difficult to finish by other methods (such as small holes, complex surfaces and small narrow grooves, etc.).

3. Electrolytic mechanical grinding composite polishing – Its principle is basically the same as electrolytic grinding. During polishing, the polishing head is connected to the negative pole of the DC power supply and the workpiece is connected to the positive pole. The electrolyte is injected into the polishing area between them by a hydraulic pump, and the polishing head rotates at a certain speed and pressure. After the DC power supply is turned on, the surface of the workpiece is dissolved by the electrolyte to form a passivation film. The hardness of this extremely thin passivation film is much lower than the hardness of the workpiece material itself, and it is easily removed by the abrasive on the polishing head. Since the process is only cycled within 0.1s, the polishing efficiency is high, the quality is good, and the cost is low.

4. Ultrasonic electric spark composite polishing – The surface of the workpiece is finished by ultrasonic grinding and spark discharge, which is more than 3 times more efficient than simple ultrasonic mechanical polishing. Its biggest feature is that it can efficiently polish small holes, narrow grooves, gaps and small precision surfaces, and the surface roughness Ra can reach 0.08-0.16μm.

5. Magnetic grinding and polishing – The magnetic abrasive is placed in the magnetic field, and the abrasive is arranged into a magnetic brush along the direction of the magnetic lines of force. When the workpiece is placed in the middle of the N-S magnetic poles and moves relative to each other, the two magnetic poles grind and polish the workpiece, and the surface roughness Ra of the workpiece can reach 0.2μm in 8-12s.

Practice has proved that polishing is a widely used and increasingly mature surface finishing method in mechanical processing. It has both the practical experience of traditional processes and the theoretical basis of modern processes. It is simple to operate and economical and practical. For many new and efficient polishing processes currently under development, they should be selected according to local conditions in combination with production conditions, and fully promoted after the expected results are achieved through process tests.