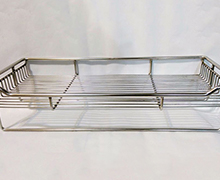

Decorative appearance

The gleaming and reflective surface is pleasing to the eye because it lacks the fine lines that are visible when using abrasive polishing.

The uniformity and luster of an electropolished surface are superior to that of a mechanically polished surface. An electropolishing system from CNCJY that is repeatable and automatic can help you raise your quality benchmarks at a low cost. Precision metal parts can be electropolished with our complete, stand-alone, proprietary electropolishing system’s small size, advanced controls, and proven durability. The design and construction of your electropolishing system will be done by our team of experts based on your needs and specifications. To learn more about CNCJY’s electropolishing equipment, contact us today.

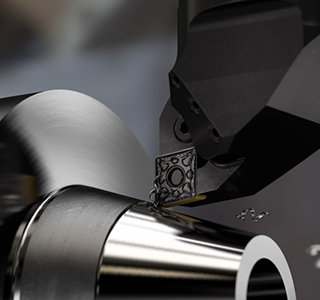

Electropolishing is an electrochemical process that removes material from a metallic workpiece, reducing surface roughness by leveling micro-peaks and valleys, and improving surface finish. It is also known as electrochemical polishing, anodic polishing, or electrolytic polishing (especially in the metallography field). Electropolishing is frequently compared to, but distinct from, electrochemical machining. It is applied to metal parts to polish, passivate, and deburr them. It is frequently referred to as the inverse of electroplating. In microstructural preparation, it can be used instead of abrasive fine polishing.

| Name | Description |

|---|---|

| ASTM B912 | Standard Specification for Electropolishing Stainless Steel Alloys |

| SEMI F17 | Specification for High Quality Electropolishing 316L Stainless Steel Tubing, Component Tube Stubs, and Fittings Made From Tubing |

| SEMI F19 | Specification for the Finish of the Wetted Surfaces of Electropolishing 316L Stainless Steel Components |

| ASME BPE | Bioprocessing Equipment |

The gleaming and reflective surface is pleasing to the eye because it lacks the fine lines that are visible when using abrasive polishing.

Electropolishing removes microscopic shards of displaced surface material that can snag and snap during normal use.

Produces a clean, easier-to-sterilize surface. Eliminates embedded contaminants that can cause corrosion.

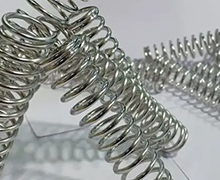

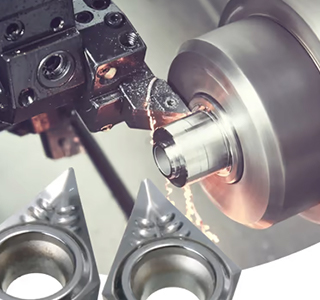

Increases operational life by removing surface fissures and cracks, thereby removing potential corrosion sites. It allows parts that must flex and bend to last longer.

Increases the life of moving parts. Improves sealing by reducing galling on threaded parts.

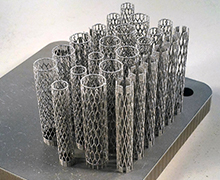

Works on delicate parts that could be damaged by tumbling. Some mechanical finishing techniques, such as grinding, buffing, milling, and blasting, can be replaced.

Can polish areas that other polishing methods cannot reach without causing damage. Treats tiny surfaces on complex components effectively.

If necessary, it can be used to slightly reduce the size of parts.

The effectiveness of electropolishing in eliminating corrosion and removing surface defects is 30 times greater than that of passivation.

Micro cracks and burrs are precisely removed by electropolishing, resulting in the lowest possible surface roughness of any metal finishing method.

The best defense against metal part corrosion is electropolishing. Download our whitepaper on corrosion resistance.

Micro surface defects are removed by electropolishing, which extends the life of metal parts that flex, rotate, twist, and bend by eliminating them.

Before beginning the electropolishing process, the metal surface must be cleaned to remove any contaminants. To ensure that the electropolishing process produces a uniform surface finish on the metal with no fine lines, contaminants such as oil and grease must be removed.

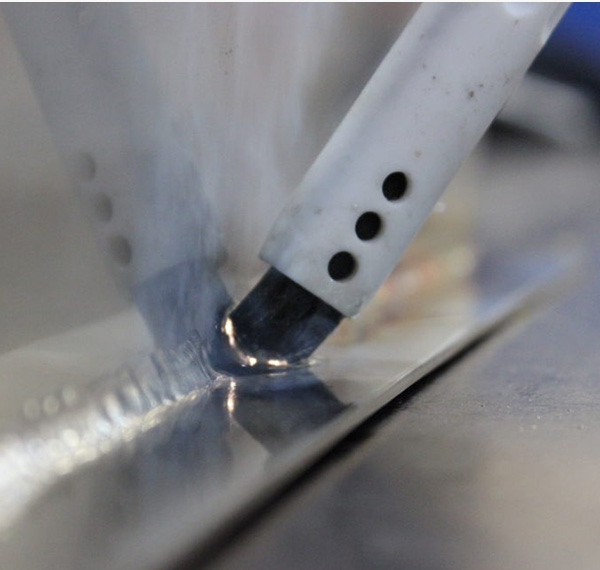

After the metal has been cleaned, the electropolishing system operates by immersing the metal part in an electrolytic bath, which is typically composed of sulfuric and phosphoric acid and is connected to a power supply. When the power is turned on, the metal part becomes anodic (+), while another metal, usually lead, copper, or stainless steel, serves as a cathode (-).

The direct current flows from the anode to the cathode at a controlled rate, removing high points on the metal surface while producing a uniform, high luster. The amount of metal removed is determined by the electropolishing bath, temperature, speed, and alloy. This process is also used for micro- and macro-deburring because it selectively removes metal ions from high points on the surface without etching it.

Following the electropolishing process, a post-treatment is required to prevent staining. To ensure a consistent finish, any residual electrolyte and chemical by-products, such as phosphates and sulfates, must be removed. If the metal is not rinsed of these acid residues, white spots may appear on the metal surface after drying.

Copyright 2024 CNCJY Project By KALI, All Rights Reserved.