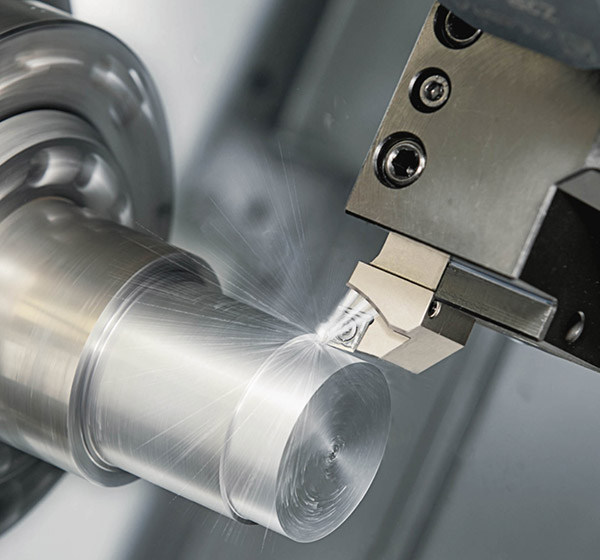

Heat buildup

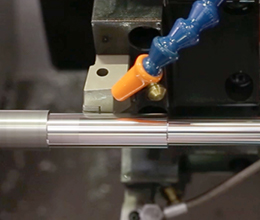

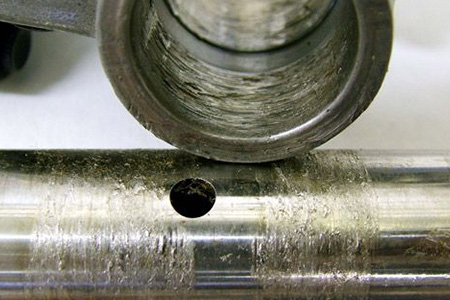

Titanium alloys can be more difficult to machine than aluminum alloys, which are more commonly used. As a result, tool wear and heat buildup at the point of contact can both be increased. Reduce the CNC machine RPM while increasing the chip load for these harder titanium alloys. You can also reduce the stress on your cutting tools by using a high-pressure coolant. While Grades 1–2 of titanium are less likely to overheat, caution should still be taken when working with this material.