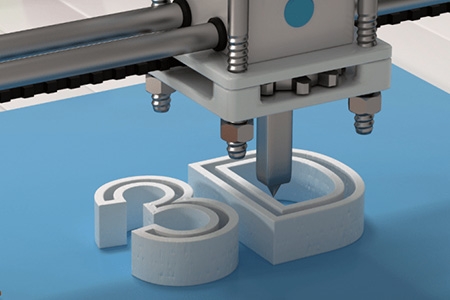

3D Printing

3D printers produce three-dimensional items directly from CAD models by building material in layers until a complete physical part is generated. These parts can then be removed from the printer and used in other applications.