Experience and capabilities to deliver machining brass parts in specified tolerances.

Brass CNC Machining – CNC Machining Brass Services and Parts Supplier

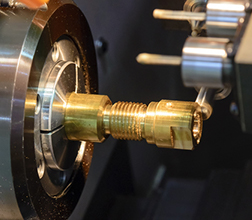

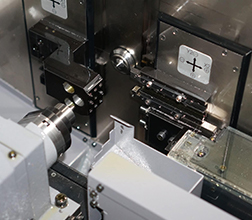

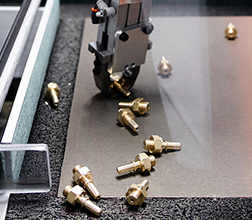

Brass is an alloy of copper and zinc, its aesthetic appeal and outstanding machinability make it an ideal material for the CNC machining process. CNCJY is a precision machine shop that specialized in brass CNC machining services and parts for worldwide clients. To manufacture highly accurate, custom CNC machining brass parts and components, we use advanced turning and milling machines as well as 5-axis machining centers. We’ve spent more than 15 years understanding different materials and their properties, extensive experience allows us to create custom CNC turning brass parts and CNC milling brass parts with high precision and exact specification as your request. Our brass machined parts and products are widely used in commercial and industrial use, reasonable prices and efficient production will save some cost for your project. Whether you need small or large batch machining brass parts, premium quality will be guaranteed.

Common Alloys and Specifications of CNC Machining Brass

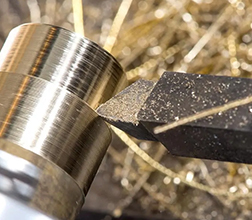

Brass is one of the easiest materials to machine in CNC manufacturing, it is also valued because of its advantageous characteristics and properties including bright appearance, low friction, corrosion resistance, wear resistance, and good overall conductivity. Changing the content of zinc and copper will create a series of brass alloys with different properties.

| Properties | A relatively low melting point, easy to cast and machine, resistant to corrosion and wear, a good conductor of heat and electricity |

| Applications (Brass CNC Parts) | Locks, bearings, gears, valves, brackets, braces, pins, bolts, screws, builders hardware, etc. |

| Wall Thickness | As low as 0.03” or determined by the ratio of wall thickness to planar dimension |

| Maximum Size | Determined by machines and complexity of the part |

| Tolerances | As low as 0.005” or determined by the alloy |

| Lead Time | As fast as 3 days, longer for complex custom brass parts |

Alloy C260 (Bras 260 Cartridge Brass)

Brass 260, also known as yellow brass, cartridge brass and alloy 260, is mainly alloyed with copper and zinc, it has the highest ductility of the yellow brass series, excellent cold workability, and good corrosion resistance in most environments except acetic acid and some certain materials. Its workability makes C260 brass can be fabricated with cutting, forming, bending, and more processes. Typical applications of C260 brass include ammunition components, fasteners, lamp fixtures, locks, plugs, etc.

| Density | Hardness | Yield Tensile Strength | Fatigue Strength | Elongation at Break |

|---|---|---|---|---|

| 8.53 g/cm^3 | 53 Brinell | 75 MPa | 90 MPa | 68% |

Alloy C360 (Brass 360 or Free Cutting Brass)

Alloy C360 is referred o as a free-cutting brass with the highest machinability among all of the copper alloys, it also has exceptional strength and good corrosion resistance. Brass 360 is usually used for decorative purposes because of its smooth surface finish and gold-like appearance. The mechanical properties of C360 also make it suit for functional products and rigorous use.

| Density | Hardness | Yield Tensile Strength | Fatigue Strength | Elongation at Break |

|---|---|---|---|---|

| 8.49 g/cm^3 | 63 to 130 Brinell | 124 to 310 MPa | 138 MPa | 53% |

Surface Finishing and Post Processing Options for Brass Machining Parts

CNCJY offers a variety of metal surface finishing and post-processing options to your specifications on our brass machined components. Our finished brass parts are applied throughout a ton of industries, and we provide the most extensive selections of colors and finishes available.

Polishing & buffing

As machined

Powder coating

Brass dipping

Bead blasting

Electroplating

Brass CNC Machining FAQs

What is CNC Brass Machining?

Why is Brass Good for Machining?

Brass is one of the most commonly utilized and versatile materials due to the following advantages:

Brass is easy to machine with minimal difficulties.

Brass is a material with no sparks in machining.

Brass causes minimal to zero tool wear.

Brass is a durable and reliable material.

Extensive tools are compatible with brass rods.

Brass parts can achieve the most precise tolerances.

Brass components are widely employed in several sectors.

Brass components are suitable for situations exposed to corrosion-causing factors.

Why Should I Choose CNCJY for Brass CNC Machining Services and Parts

State-of-the-art technology to create custom on-demand parts most efficiently and precisely

A powerful combination of skilled experts and industry knowledge at our company

Hard work, clear schedule, and communication throughout the whole production cycle

Cost-effective and high quality for both prototypes and large batch production run