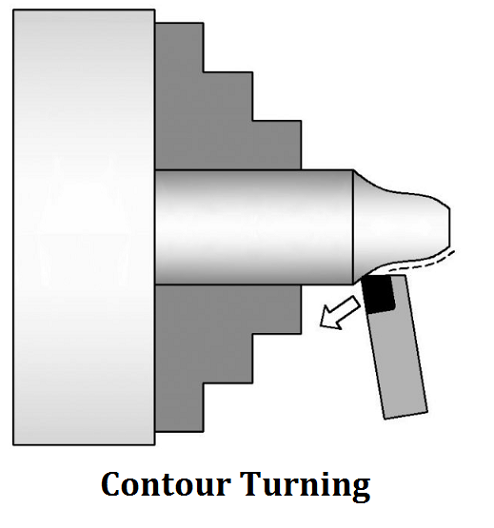

Contour turning is a special turning process for the machining of non-cylindrical workpieces. Instead of the one or two-dimensionally shaped turned pieces obtained by conventional turning systems, which are generally limited to the production of cylindrical or conical shapes, the turning process allows convexed curves, angles, and complex contours. The following guide is to provide an overview of contour turning, mainly covering what it is, how it works, the basics, what you need, where it is used, its pros and cons, and a comparison with other turning methods in each aspect.

What Is Contour Turning in a Lathe Machine?

Contour turning may be described as a form of milling wherein a cutting tool follows a predetermined course in forming a workpiece to a contour determined by such course of travel. This process is most useful in manufacturing parts with complex geometrical shapes that are not otherwise possible to machine by using live tooling, such as complex head designs, etc. Contouring turning is also important in the aerospace, automotive, and medical industries, where accuracy is key.

How Does Contour Turning Work?

In contour turning, kinematical facts are used, which make it possible to program workpiece rotation as well as tool movement in two phases simultaneously, operating in the axial direction as well as in the radial direction. This reciprocating action allows the tool to follow intricate profiles and other uneven contours as the workpiece is rotating. The shaper requires programming the machine if the required job is infrequently performed on the CNC machine, and the machine must be in the software in this case. The cutting velocity, feed, and depth of cut are the factors that must be accurately set in order to achieve the required surface finish and dimensional accuracy.

Equipment and Tools for Contour Turning

The major equipment for completing a contour turning operation is a lathe machine, while there are multiple cutting tools to choose from.

1. Lathe Machines

The heart of the contour turning process is a customized lathe for fine machining. The CNC (computer numerical control) lathe is the most versatile and commonly used machine tool, which provides the possibility of performing all of the operations under the tool path control. They incorporate high-resolution encoders, high-performance servo motors, and rigid, accurate ball screws to provide peak performance.

2. Cutting Tools

The choice of cutting tools applied in incutting profile turning is the point of primary importance. It is possible to use common tools such as cylindrical external tools, grooving tools, etc., in practice, but special contouring tools must be used to produce some geometries. The geometry of the cutting instrument needs to be designed to coincide with the cutting trajectory that is to be generated and machined for optimal material removal and to obtain a much improved surface finish.

3. CAD/CAM Software

Conical turning is simulated using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software. CAD software makes complicated contour programming CAM software routes the CNC program automatically. This is also incorporating design into the manufacturing process, so it is simpler to fabricate more complicated parts.

Where Are Contour Turning Applied?

Contour turning is used in various industries because of its capability of generating complex shapes.

1. Aerospace Industry

In aerospace, contour turning is used for the manufacture of components like blades of turbine, engine parts of aircraft. Tight tolerance is required for these parts. They are complex in shapes and sizes to meet optimum performance and protection.

2. Automotive Industry

In automotive, contour turning is utilized for components, including crankshafts and camshafts, that require precise contours for optimal performance and smooth functioning. The performance of vehicles is improving with their capability of realizing complex geometries.

3. Medical Device Manufacturing

Surgery instruments and prostheses, aesthetic products in general, are frequently requested to be accurate and with fine surfaces. Requirements arise in the finishing contour turning and in patient-adapted components for the quality of the care, fulfilling these same requirements.

4. Mold and Die Production

Mold and die shops are also attracted by contour turning’s capability for creating complex cavity shapes and profiles. This accuracy is important for manufacturing precise parts of plastic or metal.

5. Artistic Applications

Contour turning is also used by decorative turners in the making of sculptured or decorative work. This flexibility is furthermore ornamental in these articles.

Advantages of Contour Turning

- Design Flexibility: Manufacturers are free from the constraints of traditional round cross-sections and use a variety of geometrical profiles to fulfill functional or aesthetic requirements.

- Production Capacity: After programming, the automatic machining can be performed independently of the operators or other staff, not only reducing the construction period but also avoiding human error.

- Superior Component Quality: With proper control of the tool path and cutting conditions, contour turning holds promise for accuracy and surface finish. The precision guarantees the long life and working reliability of the machine elements.

What Challenges Are We Facing in Contour Turning?

Whilst having its own benefits, contour turning is not an easy task:

1. Technical Requirements

Both machinists and programmers need to be highly skilled in their respective expertise. To achieve accurate contours, extensive knowledge about lathe operation, cutting tools, and CNC programming is required.

2. Toolpath Planning Complexity

Complex contour toolpathing can be complicated and intense. Even tiny programming mistakes can result in tremendous deviation from the finished product, so it requires a lot of calculations, all done on the fly.

3. Cutting Forces and Vibration

Contour turning imposes varying forces on the tool, which may cause it to vibrate. This vibration negatively influences machining precision and surface quality, which necessitates reducing its impact.

Manual Contour Turning vs. CNC Contour Turning

There are different ways to complete the contour turning, which one to choose? Consider the following factors before determining that.

| Feature | Manual Contour Turning | CNC Contour Turning |

|---|---|---|

| Operational Method | Relies on machinist skill and experience | Uses pre-programmed CNC systems |

| Precision | Limited precision, dependent on the operator | High precision, tolerances as tight as ±0.0001 inches |

| Complexity Handling | Suitable for simple shapes | Capable of machining complex contours |

| Efficiency | Slower, less efficient | High efficiency, suitable for mass production |

| Setup and Programming | No programming required, manual setup | Requires CAD/CAM programming, quick modifications are possible |

| Cost | Lower initial costs but higher labor costs | Higher initial costs with lower per-unit costs in mass production |

Contour Turning vs. Form Turning

Form turning is another type of turning machining process that can be performed on lathes.

| Feature | Contour Turning | Form Turning |

|---|---|---|

| Definition | Dynamic toolpath for complex shapes | Uses a form tool to create specific contours |

| Cutting Tools | Standard and specialized contouring tools | Form tools shaped to match the desired contour |

| Machining Process | Involves multi-axis coordinated movement | Straightforward, linear, or circular motion |

| Geometric Flexibility | Can create diverse and intricate shapes | Limited to simple and regular contours |

| Applications | Aerospace, automotive, and medical devices | Mass production of simple-shaped parts |

| Precision and Surface Quality | High precision, complex surface finishes | Good precision, but limited to simpler shapes |