Multi Jet Fusion (MJF) is a newer addition to 3D printing technologies. It is capable of creating plastic components with high durability and accuracy. In this post, we will focus on MJF 3D printing technology, including its principles, processes, equipment, materials, and comparisons with other printing techniques.

What Is Multi Jet Fusion 3D Printing – MJF 3D Printing Definition

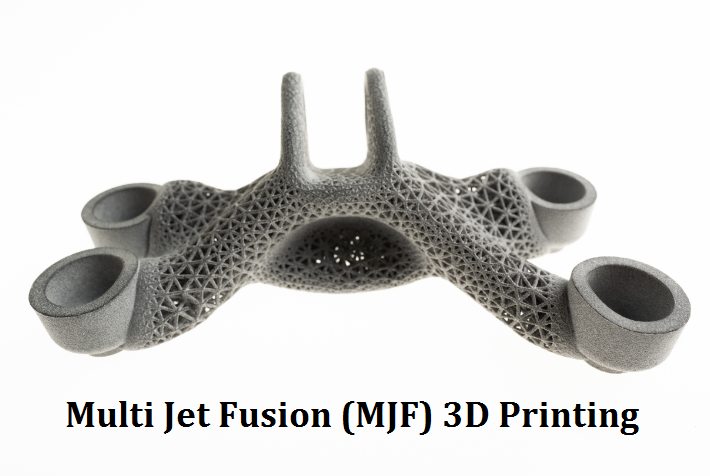

MJF 3D printing is one of the additive manufacturing technologies created by HP that uses a powder bed method to construct components. MJF has been under development since 2016, and within such a short timeframe, it has become one of the most preferred 3D printing technologies. Multi Jet Fusion is well-known for its ability to produce delicate, complex plastic parts and components with exceptional surface finish and mechanical strength. Its cost and time efficiency offer greater advantages compared to older methods. MJF 3D printing helps in all stages of the product life cycle, including prototypes to final functional products. MJF uses polymer layer fusion, which is different from other printing methods since infrared lasers are utilized. This also helps with proper and uniform heating within the build area. There is an improvement in the physical features and the printing times for the workpiece. Parts produced with MJF technology demonstrate a remarkable tensile strength and detail resolution capture of fine features.

HP already had a great advantage for MJF development due to their experience in inkjet printing and complex mechanical systems. HP had been looking for a fully automated system in the 90s due to the absence of fast 3D printing technologies. Sustained motivation for the development of MJF came from the large powder bed of MJF since it provided simpler post-processing compared to other additive manufacturing techniques, such as SLS.

In addition to high speed, certain applications benefit from the isotropic mechanical properties MJF offers. It also allows for intricate geometric shapes as unfused powder assists throughout the printing process. Compared to SLS, which only recovers 50-70% of excess powder, MJF has a better material recovery rate, where 80% of excess powder is reusable.

How MJF 3D Printing Works – The Process of MJF Printing

Multi Jet Fusion (MJF) is a form of 3D printing technology that falls under Powder Bed Fusion (PBF). It fabricates components in layers using thermoplastic powders. While laser methods of MJF printing differ, these printers use inkjet technology to apply two agents: a fusing agent, which binds, and a detailing agent, which enhances clarity. The infused regions are subsequently heated by infrared sources that energize those regions, turning the powder into a liquid and then solidifying into layers. This continues until the part is completed, while excess powder helps support the structure during building.

- Step 1: Like with any 3D printing, an operator must first create a CAD model, which is then printed. This time, the model is printed with thermoplastic powders. The MJF printer comes preloaded with the nylon thermoplastic powder.

- Step 2: The system spools a layer of thin powder. To build the part, jet heads deliver the detailing and fusing agents on the surface that needs binding while edge detailing is applied simultaneously.

- Step 3: An infrared heat source increases the temperature in the areas with detailing agent to melt the powder that contains the fusing agent. In this scenario, the build platform will lower in preparation for the next layer after this step.

- Step 4: As part of the cycle, the MJF recoater applies another layer of powder, which, together with the preceding one, will undergo agent application and heating, leading to complete part synthesis.

- Step 5: The operator starts with the depowdering (removal of excess powder) after the build is completed and the chamber is cooled. The parts are then bead blasted to improve the surface finish. All excess powder recovered is stored and classified for later use.

What Is an MJF 3D Printer (MJF Printing Machine) & How to Choose?

Everyone knows HP MJF 3D printers are one of the industry leaders. These MJF 3D Printers have some notable features, like having a powder bed composed of nylon thermoplastic materials, which allows for layer-by-layer construction. Furthermore, they have inkjet print heads that deposit fusing and detailing agents onto the powder. During the layering process, the powder is selectively melted. This is done by applying thin layers of powder onto the build surface, then applying fusing agents to each layer followed by infrared heating to melt the powder. This repetitive process is done until the model is finished. The benefits of this approach are numerous in automotive, aerospace, and medical fields for functional prototypes and parts that are used in the end with complex and branched geometrical shapes. Some advantages of MJF 3D printers are strong mechanical strength and resolution of parts, high recycling rates of unused powder, and lower material waste.

Things To Consider When Choosing Your Ideal 3D Printer

- 3D printer categories: In business, there are four main categories that define 3D printers: VAT Photopolymerisation, Powder bed fusion, Extrusion-based systems, and Material jetting. Each category has specific technologies and materials used for construction. For example, VAT Photopolymerisation covers both Stereolithography (SLA) and Carbon DLS, while Powder bed fusion incorporates both Selective Laser Sintering (SLS) and HP Multi Jet Fusion (MJF). Fused Deposition Modelling (FDM) is part of Extrusion-based systems, and Polyjet is part of Material Jetting.

- Features of the printer: Every technology has its distinctive features. Surface finish, resolution, biocompatibility, and color capabilities provide distinguishable features that aid selection. Consider color MJF, which boasts a porous surface finish coupled with high resolution, medium mechanical strength. FDM offers lower mechanical strength, a step-like surface finish, lower resolution but full color printing.

- Pricing: Each type of printer comes equipped with a unique cost that rises with an increase in volume and fidelity of print output. Balance these factors for more cost-effective options. For instance, FDM printers sit at the lowest price of €2000, while MJF printers start at €48,000.

- Build volume: When you’re thinking about the size of parts you want to print, it is important to choose a printer with the right build volume. Different technologies have different maximum build volumes. MJF has a build volume of up to 380 x 284 x 380 mm, whereas FDM can have a build volume of up to 914 x 610 x 914 mm.

- Post processing: Pay special attention to surface finishing and coloring as they constitute an additional step in the process. These functions are easier on lower-cost printers that lack these features.

Do MJF 3D Printers Have Multi-Color Functionality?

Depending on the model, MJF3D printers can perform multi-color printing. HP has created full-color MJF printers such as the HP Jet Fusion 580/581, which enables the production of intricate and colorful parts in one printing cycle. They use a mixture of colored agents and standard fusing agents to carry out multi-color printing. Still, most MJF printers are basic models that only make gray parts. Multi-color printing helps enhance the look of the parts for products and models that are intended for sale.

What Materials Are Used in Multi-Jet Fusion 3D Printing? – MJF 3D Printing Materials

Other materials can be applied, but nylon is greatly used in MJF printers.

| Material | Type | Print Speed | Cost per Part | Post-Processing | Applications | Surface Finish |

| Nylon (PA12) | Polyamide | Fast, several parts per hour | Moderate, economical | Depowdering, bead blasting, and other treatments | Functional prototypes, end-use parts, housings, enclosures | Generally smooth, good detail, may need post-processing |

| Nylon (PA11) | Polyamide | Fast, similar to PA12 | Moderate, slightly higher than PA12 | Similar to PA12 | Mechanical components like hinges, functional parts | Similar to PA12, it may require finishing for aesthetics |

| Polypropylene (PP) | Thermoplastic | Slightly slower than nylon | Similar to nylon | Depowdering, optional sanding, or coating | Automotive, medical, fluid tanks, etc. | Smoother than nylon, less detailed, finishing may be needed |

| Glass-Filled Nylon | Reinforced Polyamide | Similar to nylon, slightly longer | Higher than standard nylon | Careful depowdering, bead blasting, machining | Structural parts, automotive components, jigs/fixtures | Rougher surface, may need finishing |

| Carbon Fiber-Reinforced Nylon | Composite | Slower than standard nylon | Generally higher due to carbon fiber | Similar to glass-filled nylon, careful finishing is required | High-performance parts like drones, aerospace components | Less smooth, may require careful finishing |

| TPU (Thermoplastic Polyurethane) | Flexible Material | Slower due to flexibility | Usually higher than rigid materials | Depowdering, minimal finishing unless aesthetics required | Flexible parts like seals, gaskets, and protective covers | Generally smooth and flexible, details can vary |

MJF vs SLS 3D Printing: What Are the Differences?

For HP, printing in MJF is part of daily business functions. The rest of the process employs an inkjet array to apply fusing and detailing agents on a layer of thermoplastic powder. Each layer is refined using infrared light, which is a very quick method of achieving fine details on parts. With MJF, the high efficiency and high recycling rates of unused powder, as well as isotropic mechanical properties which provide consistent strength in all directions, are clear advantages over other processes. Competitively, this technology excels in building complex geometries without the need for support structures, which is useful for functional prototypes and for end-use applications. Because a laser is used to fuse powdered materials layer by layer, MJF is faster to fuse layers than SLS. While SLS point-to-point laser scanning for layer fusing is slower than MJF, complex designs are often achievable with SLS, although supports are required for overhangs. SLS parts also exhibit anisotropic strength, meaning the strength of the part depends on the orientation of the print.

| Differences | Multi Jet Fusion (MJF) | Selective Laser Sintering (SLS) |

| Technology | Inkjet array deposits fusing agents; uses infrared light to fuse powder | Laser scans and sinters powder layer by layer |

| Speed | Generally faster; claims up to 10x quicker for some applications | Slower due to point-by-point laser scanning |

| Surface Finish | Produces smoother finishes and finer details | Typically results in rougher surfaces |

| Material Utilization | Higher recycling rates (up to 80% of unused powder) | Lower recycling rates (50-70% of unused powder) |

| Mechanical Properties | Isotropic properties; consistent strength across directions | Anisotropic properties; strength varies by orientation |

| Design Flexibility | Can create complex geometries without support structures | Complex designs are possible, but may require support for overhangs |

| Cost | Higher initial investment, but more cost-effective over time | Initial costs vary; higher operational costs due to slower production |

| Post-Processing | Requires depowdering and bead blasting; minimal additional finishing | Requires depowdering, surface treatments; potential for damage during handling |