-

Are you ready to start a keyboard? When starting with the first keyboard, according to the usual method (recommended), we will directly consider the price and axis. This choice is more mainstream. Although there is no major problem, it is likely that you will not choose the most suitable keyboard for you. Given that a keyboard has a service life of at least two to three years or even more than ten years, you can have a keyboard that you prefer and will accompany you for a longer time (not only including a mechanical keyboard). So, in this issue, let’s talk about keyboard configura......

2023.2.23Published by @WCYRead More -

The more you work in front of the computer, there are one very important things you must consider, that is, health problems and incorrect posture will harm the body. At present, the most ergonomic keyboard will provide you with the highest typing function to reduce muscle pressure. Now, we are bringing you the best ergonomic keyboard recommendations for 2023. Best Ergonomic Keyboard 2023 – Top 10 Most Recommended Ergonomic Keyboards These keyboards ensure that your hands are in a natural position without unnecessary bending. In order to do this, some keyboards leave ......

2023.2.23Published by @WCYRead More -

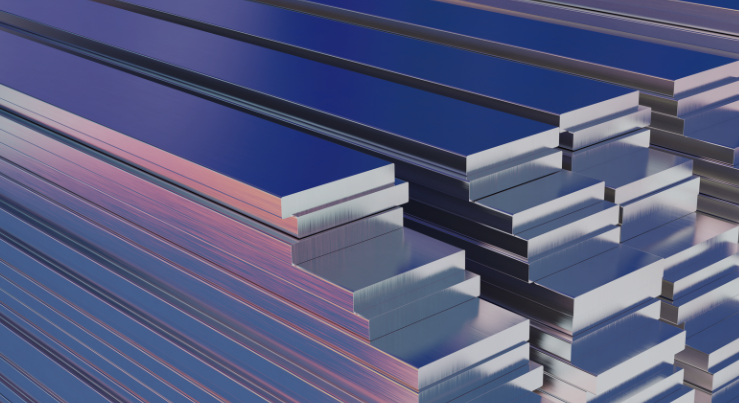

Aluminum housings are widely used in life and industrial products. In order to adapt the aluminum shell to certain environments or achieve certain functions, companies also choose different processes to treat the surface of the aluminum shell, such as anodizing, electroplating, spraying, micro-arc oxidation, etc. Anodizing is a widely used surface treatment in many processes. So why should the anodizing be used for the surface treatment of aluminum enclosures? Properties of Anodized Aluminum 1. Flatness Normal aluminum plates have a tendency to have uneven surfaces. The surfac......

2023.2.21Published by @ZNRead More -

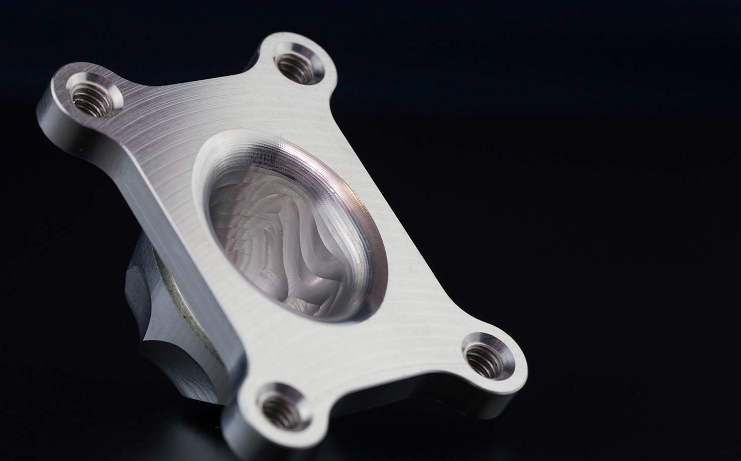

Precision parts and products made of aluminum alloy are popular due to the material’s light weight and exquisite appearance. Additionally, the material is finding more and more applications in a variety of industrial fields and everyday necessities. People’s demand for a wide variety of products is growing at an ever-increasing rate as a direct result of the relentless march of scientific and technological progress. As a result of this, the market demand for products made of aluminum alloy is also increasing at a rate that is comparable to the rate at which the technical req......

2023.2.21Published by @ZNRead More -

CNC copper processing technology involves using computer numerical control (CNC) machines to manufacture copper parts and components. The production process typically involves the following steps: Making a digital design of the copper part or component using computer-aided design (CAD) software is the first thing that needs to be done in order to get the manufacturing process started. Following the completion of the design, the next step is to write a program for the CNC machine that will be used to fabricate the component of the product. By following the instructions provided by thi......

2023.2.17Published by @ZNRead More -

A CNC mechanical keyboard is a type of computer keyboard that utilizes individual mechanical switches for each key, as opposed to the rubber dome switches that are used in the majority of mainstream keyboards. These switches can be found on a standard computer keyboard. The process of creating the switches and components of the keyboard that is referred to as “CNC” (which stands for “computer numerical control”) is a precise manufacturing process. Durability, tactile feedback, and the ability to be customized are distinguishing characteristics of CNC mechanical k......

2023.2.17Published by @ZNRead More -

With the increasing work pressure, the work intensity has also increased. The company’s ordinary notebook keyboard is more boring! Many people have heard before that the green axis keyboard in the peripheral keyboard has a crisp sound when tapping, and it is very decompression! After asking them, I bought a K320 blue switch keyboard of Durgord. This keyboard is inexpensive, cost-effective, and suitable for newcomers. In this article, I introduce everything about this keyboard. Appearance This keyboard has a strong sense of weight after it is taken out. The outer package ......

2023.1.31Published by @WLPRead More -

With the improvement of the quality of life, many people begin to consider or have started to improve their work environment. Buy laptops, keyboard and mouse, headphones, and even office chairs at your own expense to improve your comfort and office efficiency. You can see all kinds of keyboards. If you are a senior digital player, you should pay more attention to two points when selecting the office keyboard. First, you should select the big brands. The first-line big factories have better workmanship and more guaranteed quality. You can use it safely for many years. Second, of course, ......

2023.1.31Published by @WLPRead More