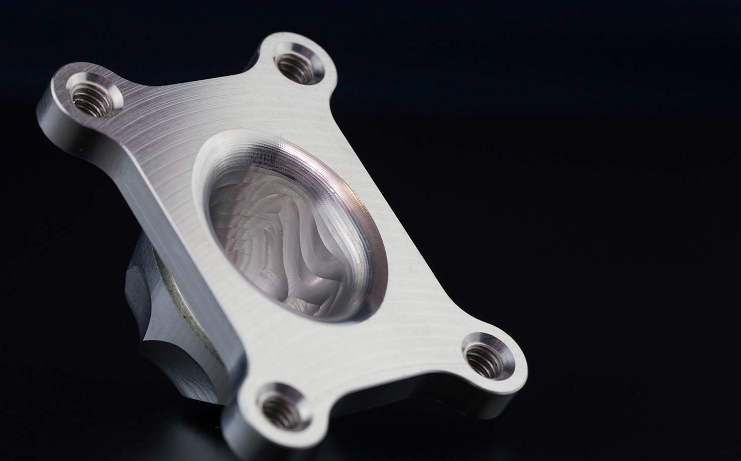

Precision parts and products made of aluminum alloy are popular due to the material’s light weight and exquisite appearance. Additionally, the material is finding more and more applications in a variety of industrial fields and everyday necessities. People’s demand for a wide variety of products is growing at an ever-increasing rate as a direct result of the relentless march of scientific and technological progress. As a result of this, the market demand for products made of aluminum alloy is also increasing at a rate that is comparable to the rate at which the technical requirements for these products are increasing. Aluminum alloy CNC processing manufacturers summarize the process skills in the processing process and the problems that should be paid attention to in aluminum alloy CNC processing in order to meet people’s demand for the diversity and high quality of aluminum alloy shell products. This is done in order to meet people’s demand for aluminum alloy shell products that are made of aluminum alloy.

Aluminum Alloy CNC Processing Skills Guide

In order to improve the economic benefits of the enterprise, we must do a good job in the details, solve unnecessary technical problems, and let customers trust our products more. The following seven points are about the skills that need to be paid attention to in aluminum alloy cnc processing.

1. The requirement of CNC machining skills is that the control system can logically process the program specified by the control code or other symbolic instructions, and decode it through the computer, so as to make the machine move and process the parts. The blank is processed into semi-finished parts through tool cutting.

2. CNC cutting is a processing method that makes the cutting process more reasonable, and is also a common process of aluminum alloy precision machining. It uses end milling cutter with multi-directional cutting function, spiral cutting interpolation and contour cutting interpolation, and it uses as few tools as possible to process a small number of holes.

3. Ball end milling cutter with spiral interpolation method can be used for continuous processing of taper hole; Boring and chamfering can be carried out by using ball end milling cutter and spiral interpolation bit; The end milling cutter can be used for semi-precision machining and precision parts machining of holes with contour cutting interpolation; The end milling cutter used for thread processing can be used to process various threaded holes with spiral interpolation method. The author reminds you that if the high-precision hole of any size is processed with high-efficiency aluminum alloy precision parts, the tool interpolation function can be used. Especially when high-speed milling is used, the load of each cutter tooth is relatively light, so the same coated carbide end milling cutter can be used for high-speed and high-precision hole processing of a variety of processed materials. In addition, in the cnc machining process of aluminum alloy, it is necessary to master the processing skills of processing technology drawings.

4. Select a reasonable cutting amount. The staff shall select the cutting speed according to the material to be processed, hardness, cutting state, material type, cutting depth, etc. These conditions are necessary to effectively reduce machine wear.

5. Select the appropriate tool. Generally speaking, it is better to select high strength and durable tools for rough turning, which can better meet the requirements of rough turning.

6. Select a reasonable fixture. The parts shall fully meet the needs of the machine to reduce unnecessary positioning errors and select special clamping tools.

7. Determine a reasonable processing route. Try to shorten the machining route and reduce the wear of the machine.