-

This article introduces “office use” keyboards, so they are basically equipped with a relatively complete set of keyboards (with special aluminum alloy keyboard cases), or ergonomically designed keyboards. The price is not too low. Both membrane keyboards and mechanical keyboards are involved. Which Keyboard Is Best for Office Use – 2023 Best Keyboards 1. Logitech MX KeysThis keyboard is considered by many to be the best office keyboard of Logitech. It has a lot of advantages: the touch is benefited from the adjustment of Logitech, the clean sound is still sm......

2023.1.31Published by @WLPRead More -

Keyboard is the main equipment for computer input. Nowadays, there are more and more situations in which computers are used in the work and life of society. Long-term use of computers requires high quality of keyboard and high ergonomic requirements of keyboard. At present, there are a variety of keyboards in the market. How to choose a suitable keyboard? What is the basic knowledge of keyboard? I have searched the Internet for a long time, but there is no simple and clear answer. Or some of the answers are special technologies, which are more complicated and confusing after reading. To......

2023.1.31Published by @WLPRead More -

The improvement of the quality of life has led to the emergence of a large number of “new” things. Even the keyboards closely related to our daily work and entertainment have also derived many thin film keyboards, mechanical keyboards and customized keyboards from the early typewriter keyboards. Not only that, keyboard manufacturers also launched 104 keys, 96 keys, 87 keys, 68 keys and even 40 keys for different typing groups, which is commonly known as XX keyboards.In the standard term, “arrangement” refers to the key assembly sequence of the keyboard, that is, ......

2023.1.31Published by @WLPRead More -

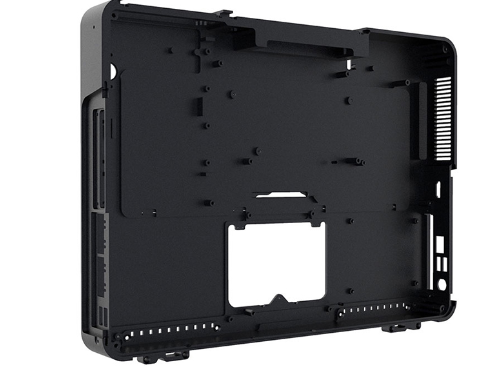

Nowadays, the case material of many electronic products is mainly aluminum alloy. The aluminum alloy case has become one of the mainstream products in the electronic industry. The cases of different products have different quality. The quality of the aluminum alloy case is highly valued by customers. Many manufacturers are prone to scrap products in the processing of the aluminum alloy case. How can we prevent this phenomenon? Today, we will introduce you the methods to prevent the scrap of aluminum alloy case. How To Prevent The Scrap of Aluminum Alloy Case/Shell? 1. Extr......

2023.1.31Published by @WLPRead More -

At present, with the rapid development of digital electronic products and the increasingly fierce market competition, consumers have particularly high requirements for “light and thin” 3C products. Therefore, the processing and manufacturing technology of 3C products needs to make breakthroughs in materials, processes and other aspects. Among 3C materials, magnesium alloy materials have become the new darling of raw materials. First of all, in practical applications, magnesium alloy is the lightest, accounting for about two-thirds of aluminum and one quarter of iron, whic......

2023.1.30Published by @WLPRead More -

CNC machining customization is a new technology emerging in recent years. Before that, we all used traditional die stamping or manual assembly. Now, more and more manufacturers have adopted CNC machining and customization equipment to produce products. For electronic products, CNC machining and customization equipment can produce a variety of parts of different shapes and sizes, and can also assemble them into one. So when we use electronic products, we often process and customize the shell of the product. What role can custom CNC machining play in the product shell/case? Mobile phone p......

2023.1.30Published by @WLPRead More -

A CNC Aluminum Keyboard is a kind of computer keyboard that is created utilizing Computer Numerical Control (CNC) manufacturing method. The keycaps and case of the keyboard are constructed of aluminum, which gives it a quality appearance and feel. CNC Aluminum keyboards are typically praised for their durability, typing feel and are liked by gamers and typing lovers. Next, we will soon demonstrate how to pick out the benefits of a CNC aluminum alloy keyboard shell. How To Choose The Best Aluminum Alloy Keyboard Shell Manufacturer We hope that after reading this, you will k......

2023.1.30Published by @WCYRead More -

Replacing a set of personalized keycaps for the beloved mechanical keyboard is something many players will do. Do you know the advantages and disadvantages of common materials for custom keycaps? Today, let’s talk about the processing technology of key and cap characters to see how they are different. At present, laser engraving technology is the most widely used in machinery. When manufacturing the key cap, the manufacturer shall add some special foaming agent into the key cap. Then the laser is used to ablate the surface of the key cap, and the ablated part will present the oppo......

2023.1.30Published by @WCYRead More