-

With the continuous advancement of technology and the increasing demand for personalized products, the keyboard, as one of the important ways of human-computer interaction, is also constantly evolving and innovating. In this space, the best new CNC-machined aluminum keyboard of 2023 is undoubtedly the OnePlus Keyboard 81 Pro. First off, the OnePlus Keyboard 81 Pro looks and feels amazing. It features a durable aluminum alloy casing that is precision CNC machined for exquisite craftsmanship and a high-end feel. The keycaps are made of high-quality PBT material, which provides a comfor......

2023.8.18Published by @ZNRead More -

The e-sports equipment of e-sports professional players is an important tool for their competition. Different sports and players may have different preferences and needs. In this article, we will introduce some gaming mouse and keyboard brands and prices for professional gaming players, as well as their features and advantages. Gaming Mouse The e-sports mouse is the main operating device for professional e-sports players. It needs to have the characteristics of high precision, high response speed, high durability, high comfort, and high customizability. Based on our search res......

2023.8.11Published by @ZNRead More -

Building your own mechanical keyboard is a fun and challenging project. Here are some steps to help you customize and assemble your own mechanical keyboard. Step 1: Design and customize the keyboard layout – Keyboard layouts include full size, TKL (no numeric keypad), 75%, 60%, 40%, etc. Choose a layout that suits your usage habits and needs. The full-size keyboard has all the standard key positions for users who need a numeric keypad and function keys. The TKL keyboard omits the numeric keypad and is more compact. The 75%, 60%, and 40% keyboards further reduce the size ......

2023.8.11Published by @ZNRead More -

CNC machining is a versatile manufacturing process that is compatible with a wide range of materials. Aluminum machining is a common process in product manufacturing due to factors such as its availability in numerous grades, high machinability, and relatively affordable cost. Different types of aluminum alloys are applicable in various machining applications, including rigid architectural components and aerospace parts manufacturing. The guide aims to provide a quick comparison of five common aluminum alloys for machining, discussing their compositions, common applications, and industr......

2023.8.2Published by @ZNRead More -

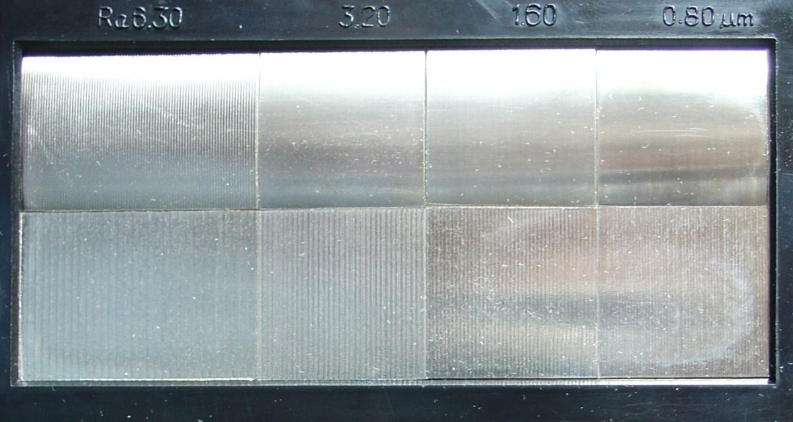

The choice of surface finish for CNC machining depends on the application, material, machining method, and cost of your part. You can use roughness comparison boards to differentiate the roughness of CNC machined surfaces. A roughness comparison plate is a tool for testing surface roughness and it is available in different grades from 0.05 to 25 microns. You can compare the comparison plate to the CNC machined part surface to find the closest grade. Alternatively, you can use a roughness gauge to measure the roughness of a CNC machined surface. A roughness meter is an instrument used to......

2023.8.2Published by @ZNRead More -

In the brass surface treatment process, brass passivation is commonly used to prevent rust and corrosion on CNC machining parts. So, how to deal with brass CNC machining parts to prevent rust? How to Clean Brass CNC machining parts degreasing To clean brass CNC machining parts and degrease them thoroughly, you can follow these steps: -Safety precautions: Ensure you have proper ventilation and wear protective gloves to protect your hands. -Disassemble the parts: If possible, disassemble the brass parts to clean them separately. This enables better access to all surfaces. ......

2023.7.18Published by @ZNRead More -

CNC machining of curved surface parts typically follows the machining rules of CNC machining centers, which include rough machining, semi-finishing, finishing, and detail processing. However, when dealing with free-form curves and surfaces that cannot be clearly expressed by geometric or mechanical drawings, the primary challenge arises during the roughing stage of the machining process. Machining centers rely on precise instructions and toolpaths to accurately shape the workpiece. While geometric and mechanical drawings can effectively convey the dimensions and shapes of standard fe......

2023.7.18Published by @ZNRead More -

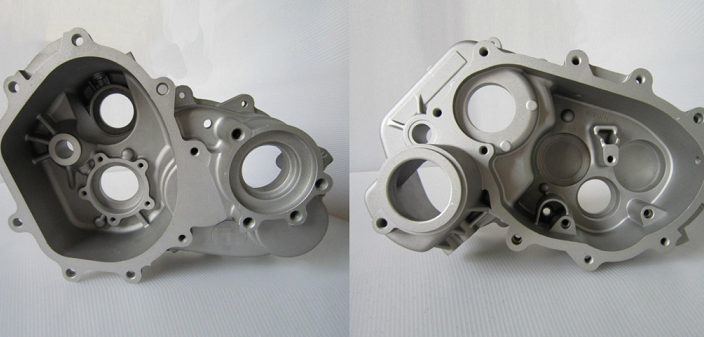

Aluminum die casting is a widely used manufacturing process for producing complex and precision components. However, like any manufacturing process, it is not immune to defects. Understanding the causes of these defects and implementing effective solutions is crucial for ensuring high-quality aluminum die castings. In this article, we will delve into the causes of various defects commonly found in aluminum die castings and explore potential solutions. 1. Porosity Porosity refers to the presence of voids or gas pockets in the casting. It can significantly compromise the mecha......

2023.7.18Published by @ZNRead More