Steel is primarily made of iron and carbon. The process of making steel involves the reduction of iron ore to produce iron, which is then combined with carbon and other elements to create different types of steel.

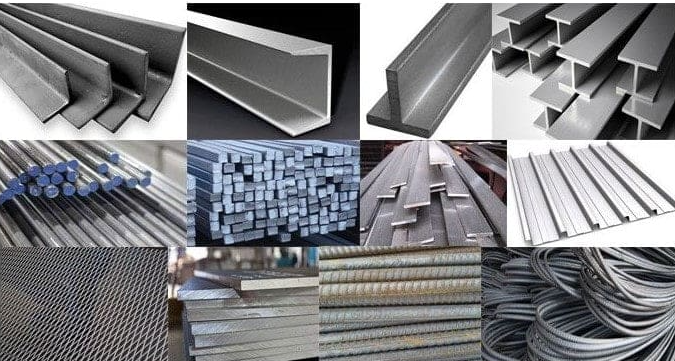

Types & Properties of Steel

Steel is an alloy of iron carbon, and sometimes other elements. Because of its high tensile strength and low cost, it is a major component used in buildings, infrastructure, tools, ships, automobiles, machines, appliances, and weapons. There are many different types of steel, each with unique chemical compositions and properties:

- 1. Carbon Steel: This is the most widely used kind of steel. Its main alloying element is carbon and it can be divided into three groups depending on the amount of carbon content:

-Low Carbon Steel: Also known as mild steel, it contains 0.05-0.25% carbon. It is malleable and ductile, has high impact strength, and is easily machined and welded. However, it’s less strong and provides less resistance to wear than higher carbon alloys.

-Medium Carbon Steel: Contains 0.3-0.6% carbon. Medium carbon steel is stronger than low carbon steel, but it’s more difficult to form, weld and cut.

-High Carbon Steel: Contains 0.6-1.4% carbon. High-carbon steel is very strong and is often used for high-strength wires and springs.

- 2. Alloy Steel: This type of steel is characterized by the additional elements that are added to enhance certain properties like strength and durability. These alloying elements include manganese, nickel, chromium, molybdenum, vanadium, silicon, and boron. Less common alloying elements include aluminum, cobalt, copper, cerium, niobium, titanium, tungsten, tin, zinc, and zirconium.

- 3. Stainless Steel: This is a highly corrosion-resistant steel that contains a minimum of 10.5% chromium. Other elements are added to enhance its structure and properties such as formability, strength, and cryogenic toughness. It’s used in a variety of applications from cutlery to surgical equipment, aircraft, and even architecture.

- 4. Tool Steel: Tool steels contain tungsten, molybdenum, cobalt, and vanadium in varying quantities to increase heat resistance and durability, making them ideal for cutting and drilling equipment.

- 5. Weathering Steel: Also known as corten steel, it contains elements such as copper, chromium, nickel, and phosphorus so that it develops a protective patina which reduces the need for painting.

What Are the Applications of Steel

1. Construction and Infrastructure: Steel is used in the construction of buildings, bridges, and other structures because of its high strength and durability. It’s also used for reinforcement in concrete structures.

A36 steel is a common structural steel in the United States. The A36 standard was established by the ASTM International.

A36 Steel Data Sheet:

- Carbon (C) content: 0.26%

- Copper (Cu) content: 0.20%

- Manganese (Mn) content: 0.80%

- Phosphorus (P) content: 0.04% max

- Sulfur (S) content: 0.05% max

- Yield strength: 36,000 psi

- Tensile strength: 58,000-79,800 psi

2. Automotive Industry: Steel is used extensively in automobiles for its strength and ability to be molded into various shapes. It’s used in the bodywork, chassis, engine components, gears, and many other parts. Advanced High-Strength Steels (AHSS) are used in the automotive industry because of their high strength and lightweight properties.

AHSS Data Sheet:

- Carbon (C) content: Varies

- Manganese (Mn) content: Varies

- Yield strength: Up to 1000 MPa

- Tensile strength: Up to 1500 MPa

3. Tool Making: Tool steels are used in the production of cutting tools, molds, dies, and other tools used in manufacturing. They’re valued for their hardness and resistance to abrasion. D2 tool steel is a high carbon, high chromium tool steel that offers a good balance of toughness, wear resistance, and hardness.

D2 Tool Steel Data Sheet:

- Carbon (C) content: 1.5%

- Chromium (Cr) content: 12%

- Molybdenum (Mo) content: 1%

- Vanadium (V) content: 1%

- Yield strength: 275,000 psi

- Tensile strength: 285,000 psi

4. Kitchen Utensils and Appliances: Stainless steel is used in the production of kitchen utensils and appliances for its corrosion resistance, ease of cleaning, and aesthetic appeal. 304 stainless steel is commonly used in kitchen appliances and utensils.

304 Stainless Steel Data Sheet:

- Carbon (C) content: 0.08% max

- Chromium (Cr) content: 18-20%

- Nickel (Ni) content: 8-10.5%

- Manganese (Mn) content: 2% max

- Tensile strength: 515 MPa

- Yield strength: 205 MPa

5. Oil & Gas Industry: Steel is used in various components of the oil and gas industry including pipelines, tanks, and drilling rigs. API 5L X65 steel is commonly used for pipeline applications.

API 5L X65 Steel Data Sheet:

- Carbon (C) content: 0.12% max

- Manganese (Mn) content: 1.60% max

- Phosphorus (P) content: 0.025% max

- Sulfur (S) content: 0.015% max

- Yield strength: 65,000 psi

- Tensile strength: 77,000 psi