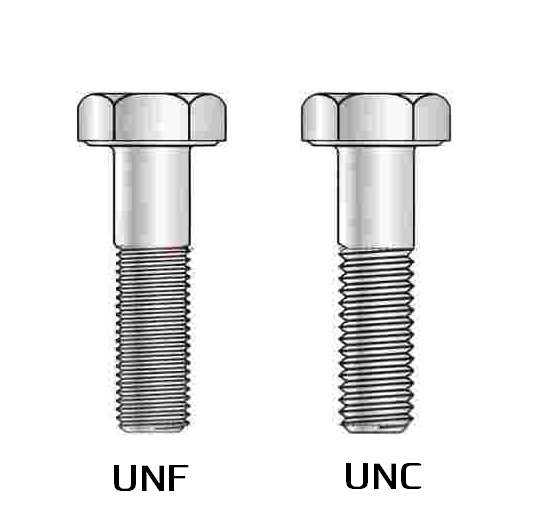

UNC and UNF are both threads defined in the Unified Thread Standard to specify their tolerances and designations. What are the differences between UNC and UNF threads, and which one to use? This article will focus on their definition, uses, differences, standard, and dimensions chart.

What Is a UNC Thread?

UNC stands for Unified National Coarse thread, a standardized thread form under the Unified Thread Standard (UTS) developed primarily in the United States. UNC threads are characterized by a coarse pitch, meaning they have relatively fewer threads per inch (TPI) compared to finer threads like UNF. The thread angle is fixed at 60°, and the thread profile includes a flat crest and root. The coarse pitch makes UNC threads easier to manufacture and assemble, especially in materials with lower tensile strength. Because of their robustness and tolerance for dirt and debris, UNC threads are less prone to cross-threading and are widely used for general-purpose fastening in engineering and construction.

What Is the UNC Thread Used For?

UNC threads are ideal for applications requiring quick assembly and disassembly without the need for extremely high strength or precision. Their coarse pitch provides better resistance to stripping in soft materials such as aluminum, wood, or plastics. Common uses include fasteners in structural components, automotive body panels, agricultural machinery, furniture assembly, and general construction bolts. Due to the ease of engagement and durability in less controlled environments, UNC threads are preferred where speed and reliability outweigh the need for fine tolerance or maximum tensile strength.

Is NPT the Same as UNC?

No. NPT (National Pipe Thread) is a tapered thread designed for sealing pipe joints, whereas UNC threads are straight (non-tapered) and intended for mechanical fastening. NPT threads create a fluid-tight seal through taper and are widely used in plumbing, while UNC threads are general-purpose fasteners without sealing capabilities.

Are UNC Threads Equivalent to ISO Thread Standards?

UNC threads are roughly equivalent in purpose and general use to ISO metric coarse threads, but they differ in thread form, pitch, and angle. UNC threads use the Unified Thread Standard profile, which is distinct from the ISO metric profile, so they are not directly interchangeable.

What Is a UNF Thread?

UNF stands for Unified National Fine thread, another thread form standardized under the Unified Thread Standard. Compared to UNC, UNF threads have a finer pitch, meaning more threads per inch, which results in a tighter, more precise fit. The thread angle remains at 60°, but the finer pitch increases the contact surface area between the male and female threads, enhancing the load distribution and tensile strength. UNF threads are typically used in applications where high precision, tight engagement, and greater strength are essential, such as in aerospace, automotive engine components, and heavy machinery.

What Is UNF Thread Used For?

UNF threads are preferred in applications that demand higher strength, precision, and vibration resistance. The finer thread pitch provides better control over torque and tension, which is critical in high-stress environments like aerospace fasteners, automotive engine assemblies, and precision instruments. The increased number of threads per inch allows for a more secure and tighter fastening, which helps prevent loosening under vibration or dynamic loads. UNF threads are widely used in heavy-duty machinery, aerospace components, and automotive assemblies where safety and performance are paramount.

UNC vs UNF Thread: What Are the Differences

- Pitch and Threads Per Inch (TPI): UNC threads have a coarser pitch with fewer threads per inch, making them quicker to assemble but less precise. UNF threads have a finer pitch with more threads per inch, providing higher precision and strength.

- Strength: UNF threads generally offer higher tensile strength due to the increased thread engagement and load distribution compared to UNC threads.

- Applications: UNC is better suited for softer materials and environments where rapid assembly is needed, while UNF is favored in high-stress applications requiring precision.

- Ease of Assembly: UNC threads are easier to assemble and less likely to cross-thread, especially in dirty or rough environments. UNF threads require cleaner conditions and more careful alignment.

- Durability and Fatigue Resistance: The finer UNF threads distribute stress more evenly along the fastener, improving fatigue resistance over UNC threads in dynamic load conditions.

UNC and UNF Thread Standard

The Unified Thread Standard (UTS) is a widely adopted system that defines the specifications for screw threads used mainly in the United States and Canada. It establishes a common thread form, along with associated allowances, tolerances, and designations, ensuring compatibility among bolts, nuts, and other threaded fasteners. Although UTS shares the same 60° thread profile as the international ISO metric thread, its dimensions are based on inch fractions rather than millimeters, reflecting its origin in countries using the imperial measurement system. The standard is currently maintained by ASME/ANSI organizations in the U.S., which oversee its updates and applications.

At its core, the UTS uses a V-shaped thread profile that is symmetrical and formed by two flanks meeting at a 60° angle. The shape is slightly truncated: the outermost eighth and the innermost quarter of the theoretical height of the V are cut off to form the actual thread profile. This modification balances manufacturability with strength and fit. The thread size is primarily identified by two parameters: the major diameter (the largest diameter measured from the outer edges of the threads) and the pitch, which is the distance between adjacent thread peaks. Instead of using pitch directly, the system utilizes the concept of threads per inch (TPI), which indicates how many threads fit within a single inch of length, simplifying specification and measurement.

The standard also explains the relationship between various diameters of the thread. For an external (male) thread such as those on bolts, the major diameter is the maximum allowable size, whereas the minor diameter (or root diameter) represents the minimum size at the base of the thread grooves. Internal (female) threads in nuts have these dimensions reversed in terms of limits to prevent interference. These careful dimensional controls ensure that nuts and bolts fit together properly without binding or loosening unintentionally.

When it comes to naming conventions, the UTS employs a combination of numbers and letters. For screws smaller than a quarter-inch diameter, an integer number is assigned, while larger screws use the inch measurement directly. This is followed by the TPI number and a series designation such as UNC (coarse), UNF (fine), or UNEF (extra fine).

Over time, the range of standard sizes has been streamlined, focusing on the most commonly used diameters and pitches for practicality and compatibility. However, special thread series such as UNS (special unified threads) exist for high-stress applications, offering higher thread counts per inch and increased strength.

UNC and UNF Dimensions in ANSI B1.1

UNC Thread Size Chart

| Major Diameter (in) |

Threads per inch (tpi) |

Major Diameter | Tap Drill Size (mm) |

Pitch (mm) |

|

|---|---|---|---|---|---|

| (in) | (mm) | ||||

| #1 – 64 | 64 | 0.073 | 1.854 | 1.50 | 0.397 |

| #2 – 56 | 56 | 0.086 | 2.184 | 1.80 | 0.453 |

| #3 – 48 | 48 | 0.099 | 2.515 | 2.10 | 0.529 |

| #4 – 40 | 40 | 0.112 | 2.845 | 2.35 | 0.635 |

| #5 – 40 | 40 | 0.125 | 3.175 | 2.65 | 0.635 |

| #6 – 32 | 32 | 0.138 | 3.505 | 2.85 | 0.794 |

| #8 – 32 | 32 | 0.164 | 4.166 | 3.50 | 0.794 |

| #10 – 24 | 24 | 0.190 | 4.826 | 4.00 | 1.058 |

| #12 – 24 | 24 | 0.216 | 5.486 | 4.65 | 1.058 |

| 1/4″ – 20 | 20 | 0.250 | 6.350 | 5.35 | 1.270 |

| 5/16″ – 18 | 18 | 0.313 | 7.938 | 6.80 | 1.411 |

| 3/8″ – 16 | 16 | 0.375 | 9.525 | 8.25 | 1.587 |

| 7/16″ – 14 | 14 | 0.438 | 11.112 | 9.65 | 1.814 |

| 1/2″ – 13 | 13 | 0.500 | 12.700 | 11.15 | 1.954 |

| 9/16″ – 12 | 12 | 0.563 | 14.288 | 12.60 | 2.117 |

| 5/8″ – 11 | 11 | 0.625 | 15.875 | 14.05 | 2.309 |

| 3/4″ – 10 | 10 | 0.750 | 19.050 | 17.00 | 2.540 |

| 7/8″ – 9 | 9 | 0.875 | 22.225 | 20.00 | 2.822 |

| 1″ – 8 | 8 | 1.000 | 25.400 | 22.85 | 3.175 |

| 1 1/8″ – 7 | 7 | 1.125 | 28.575 | 25.65 | 3.628 |

| 1 1/4″ – 7 | 7 | 1.250 | 31.750 | 28.85 | 3.628 |

| 1 3/8″ – 6 | 6 | 1.375 | 34.925 | 31.55 | 4.233 |

| 1 1/2″ – 6 | 6 | 1.500 | 38.100 | 34.70 | 4.233 |

| 1 3/4″ – 5 | 5 | 1.750 | 44.450 | 40.40 | 5.080 |

| 2″ – 4 1/2 | 4 1/2 | 2.000 | 50.800 | 46.30 | 5.644 |

| 2 1/4″ – 4 1/2 | 4 1/2 | 2.250 | 57.150 | 52.65 | 5.644 |

| 2 1/2″ – 4 | 4 | 2.500 | 63.500 | 58.50 | 6.350 |

| 2 3/4″ – 4 | 4 | 2.750 | 69.850 | 64.75 | 6.350 |

| 3″ – 4 | 4 | 3.000 | 76.200 | 71.10 | 6.350 |

| 3 1/4″ – 4 | 4 | 3.250 | 82.550 | 77.45 | 6.350 |

| 3 1/2″ – 4 | 4 | 3.500 | 88.900 | 83.80 | 6.350 |

| 3 3/4″ – 4 | 4 | 3.750 | 95.250 | 90.15 | 6.350 |

| 4″ – 4 | 4 | 4.000 | 101.600 | 96.50 | 6.350 |

UNF Thread Size Chart

|

Major Diameter (in) |

Threads per inch (tpi) |

Major Diameter |

Tap Drill Size (mm) |

Pitch (mm) |

|

|---|---|---|---|---|---|

| (in) | (mm) | ||||

| #0 – 80 | 80 | 0.060 | 1.524 | 1.25 | 0.317 |

| #1 – 72 | 72 | 0.073 | 1.854 | 1.55 | 0.353 |

| #2 – 64 | 64 | 0.086 | 2.184 | 1.90 | 0.397 |

| #3 – 56 | 56 | 0.099 | 2.515 | 2.15 | 0.453 |

| #4 – 48 | 48 | 0.112 | 2.845 | 2.40 | 0.529 |

| #5 – 44 | 44 | 0.125 | 3.175 | 2.70 | 0.577 |

| #6 – 40 | 40 | 0.138 | 3.505 | 2.95 | 0.635 |

| #8 – 36 | 36 | 0.164 | 4.166 | 3.50 | 0.705 |

| #10 – 32 | 32 | 0.190 | 4.826 | 4.10 | 0.794 |

| #12 – 28 | 28 | 0.216 | 5.486 | 4.70 | 0.907 |

| 1/4" – 28 | 28 | 0.250 | 6.350 | 5.50 | 0.907 |

| 5/16" – 24 | 24 | 0.313 | 7.938 | 6.90 | 1.058 |

| 3/8" – 24 | 24 | 0.375 | 9.525 | 8.50 | 1.058 |

| 7/16" – 20 | 20 | 0.438 | 11.112 | 9.90 | 1.270 |

| 1/2" – 20 | 20 | 0.500 | 12.700 | 11.50 | 1.270 |

| 9/16" – 18 | 18 | 0.563 | 14.288 | 12.90 | 1.411 |

| 5/8" – 18 | 18 | 0.625 | 15.875 | 14.50 | 1.411 |

| 3/4" – 16 | 16 | 0.750 | 19.050 | 17.50 | 1.587 |

| 7/8" – 14 | 14 | 0.875 | 22.225 | 20.40 | 1.814 |

| 1" – 12 | 12 | 1.000 | 25.400 | 23.25 | 2.117 |

| 1 1/8" – 12 | 12 | 1.125 | 28.575 | 26.50 | 2.117 |

| 1 1/4" – 12 | 12 | 1.250 | 31.750 | 29.50 | 2.117 |

| 1 3/8" – 12 | 12 | 1.375 | 34.925 | 32.75 | 2.117 |

| 1 1/2" – 12 | 12 | 1.500 | 38.100 | 36.00 | 2.117 |