Cutting metal and other materials is a fundamental part of fabrication, construction, and manufacturing — but not all cutting tools work the same way. Among the most widely used methods today are plasma cutters, laser cutters, and torches, each with its own strengths, limitations, and ideal applications. In this article, we’ll explain what each tool is, how it works, and highlight the key differences between them.

What is Plasma Cutter?

A plasma cutter is a tool used to cut through electrically conductive materials such as steel, aluminum, brass, copper, and stainless steel using a high-temperature jet of plasma.

How a Plasama Cutter Works

Electric Arc Creation:

The cutter sends an electric arc through a gas (like compressed air, nitrogen, or argon).

Gas Ionization:

This electric arc ionizes the gas, turning it into plasma — a superheated, electrically charged state of matter.

Metal Cutting:

The plasma jet reaches temperatures of up to 25,000°C (45,000°F), hot enough to melt metal instantly.

The force of the gas blows the molten metal away, creating a clean, precise cut.

Key Components of a Plasma Cutter

- Power Supply: Provides the electrical energy to generate the plasma arc.

- Electrode and Nozzle: Focus and maintain the plasma stream.

- Compressed Gas Source: Supplies the gas that becomes plasma and cools the torch.

- Torch or Cutting Gun: The handheld or machine-mounted tool that directs the plasma jet.

Advantages

- Cuts thick or thin metals quickly and accurately.

- Produces smooth edges with minimal finishing.

- Works well on painted or rusted surfaces.

- Suitable for manual and automated (CNC) cutting.

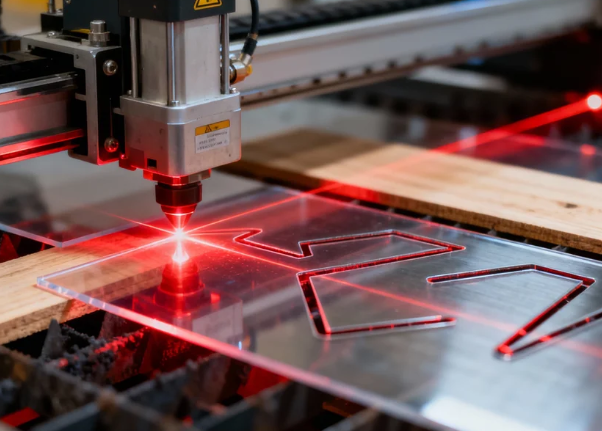

What is Laser Cutter?

A laser cutter is a machine that uses a focused beam of light (laser) to cut, engrave, or mark materials with extreme precision. Unlike plasma cutters that melt metal using superheated plasma, a laser cutter uses amplified light energy to vaporize, melt, or burn material along a programmed path.

How a Laser Cutter Works

Laser Generation:

The machine produces a powerful, concentrated beam of light using a laser source (like CO₂, fiber, or diode).

Focusing the Beam:

The laser is directed through mirrors or fiber optics and focused through a lens into a tiny, high-energy spot on the material’s surface.

Material Removal:

The intense heat (up to thousands of degrees) melts, burns, or vaporizes the material. An assist gas (oxygen, nitrogen, or air) blows away the molten residue, leaving a clean, precise cut.

Main Types of Laser Cutters

CO₂ Laser Cutter:

Uses a gas mixture (mostly CO₂) — ideal for cutting wood, acrylic, plastic, leather, and some thin metals.

Fiber Laser Cutter:

Uses fiber optics and is highly efficient for cutting metals like steel, aluminum, and brass.

Diode Laser Cutter:

Smaller and cheaper, often used for engraving or light cutting of wood, leather, and plastics.

Advantages

- Extremely high precision and clean edges

- Can cut, engrave, and mark with one machine

- Minimal waste and no contact with the material

- Works on a wide range of materials (metal, wood, plastic, paper, fabric, etc.)

What is Torch?

A torch is a handheld or machine-mounted tool that produces a controlled flame or heat source used for cutting, welding, brazing, or heating metal. It mixes fuel gas (like acetylene, propane, or hydrogen) with oxygen or air to create a high-temperature flame capable of melting or fusing metals.

How a Torch Works

Fuel and Oxygen Mixing:

The torch connects to gas cylinders — one with fuel and one with oxygen. These gases mix inside the torch handle or tip.

Ignition:

The gas mixture is ignited at the nozzle to create a steady flame.

Heat Application:

The operator directs the flame onto the workpiece for welding, cutting, or heating. The temperature and flame size can be adjusted by controlling the gas flow.

Types of Torches

Oxy-Acetylene Torch:

The most common type; used for cutting, welding, and brazing steel.

Oxy-Propane Torch:

Burns cooler than acetylene but is cheaper and safer; ideal for heating and soldering.

Cutting Torch:

A specialized torch that introduces a stream of oxygen to oxidize and blow away molten metal, enabling clean cuts.

Plasma Torch:

Found in plasma cutters — it uses an electric arc and gas to create plasma, which cuts metal instead of burning it.

Common Uses

- Metal fabrication and repair

- Plumbing and HVAC work

- Jewelry making

- Automotive and construction industries

Plasma Cutter vs Laser Cutter vs Torch: What’s the Difference?

| Feature | Plasma Cutter | Laser Cutter | Torch (Oxy-Fuel Cutter) |

|---|---|---|---|

| Cutting Method | Uses an ionized gas (plasma) jet created by an electric arc to melt and blow away metal. | Uses a high-powered laser beam to melt, burn, or vaporize material with pinpoint precision. | Uses a flame from burning oxygen and fuel gas (like acetylene) to oxidize and cut through metal. |

| Heat Source | Electric arc and compressed gas (air, nitrogen, argon). | Concentrated light energy (laser). | Chemical combustion of oxygen and fuel gas. |

| Material Compatibility | Works only on electrically conductive materials (steel, aluminum, copper, etc.). | Works on many materials — metals, plastics, wood, glass, fabric, etc. | Works mainly on carbon steel; less effective or unusable on stainless steel and aluminum. |

| Cutting Precision | High — smooth and accurate edges on metal. | Very high — capable of fine, intricate cuts and engraving. | Low to moderate — edges are rougher and may need finishing. |

| Cutting Thickness | Typically up to 30–50 mm, depending on power. | Best for thin to medium thickness (up to ~25 mm for fiber lasers). | Can cut very thick steel (up to 150 mm or more). |

| Speed | Fast for metal cutting; slower than laser on thin sheets. | Very fast and precise on thin materials; may slow on thick metal. | Slower compared to plasma and laser. |

| Surface Finish | Clean but may have slight bevel or dross on thicker cuts. | Extremely clean and precise finish. | Rough and oxidized edges. |

| Setup Cost | Medium — affordable for workshops and fabrication. | High — expensive machines and maintenance. | Low — simplest and cheapest setup. |

| Operating Cost | Moderate (requires electricity and compressed gas). | Higher (electricity, laser source maintenance, assist gas). | Low (fuel gas and oxygen). |

| Ease of Use | Easy to operate; minimal training required. | Requires training and safety precautions. | Simple but needs skill to control flame. |

| Best For | Metal fabrication, automotive work, industrial cutting. | Precision work, engraving, manufacturing, signage, electronics. | Heavy-duty steel cutting, field repair, and welding prep. |

Plasma Cutter vs Laser Cutter vs Torch, Which is the best?

Plasma Cutter: Best for fast, clean metal cutting — efficient and versatile for workshops.

Laser Cutter: Best for high-precision and multi-material cutting — perfect for detail work and production.

Torch (Oxy-Fuel): Best for thick steel and outdoor use — rugged and inexpensive, but less precise.