-

Replacing a set of personalized keycaps for the beloved CNC machining mechanical keyboard is something that many players will do. Yesterday, I counted the advantages and disadvantages of common materials of key caps. Today, I will talk about the processing technology of key cap characters to see how they are different. At present, laser engraving technology is the most widely used in machinery. When making the key cap, the manufacturer shall add some special foaming agent into the key cap. Then use the laser to ablate the surface of the key cap, and the ablated part will show the opposi......

2022.10.31Published by @WLPRead More -

The machining deformation of aluminum alloy shells, especially thin-walled shells, is a common technical problem. Therefore, our machining plant must analyze the causes of deformation and take corresponding measures to prevent it. What Causes The Deformation Of CNC Aluminum Alloy Shell & How To Fix1. The material grade and structural complexity of the aluminum sh......

2022.10.31Published by @WLPRead More -

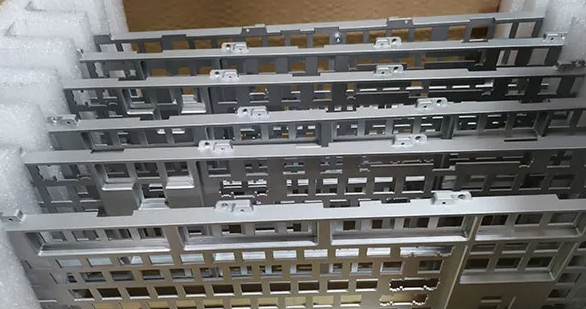

For computer enthusiasts, the metal texture of mechanical keyboard and the sound of mechanical equipment are the fun of keyboard users. The modeling design of the machine keyboard frame is one of my favorite hardware configurations. Especially in the case of glaze color and computer typing, it is very intoxicating. Nowadays, DIY keyboard has become a great pleasure for computer enthusiasts, and the design and customization of keyboard case is becoming more and more important. Sometimes choosing the right keyboard case is a headach......

2022.10.31Published by @WLPRead More -

The string pitch of a guitar refers to the distance between the string and the fingerboard (pinhead) below. When the distance is closer, the player can press the sound with less effort. On the contrary, it is more difficult. However, too small a pitch is likely to cause noise in playing. Therefore, there are indeed many technical problems and rules of thumb to pay attention to when adjusting! However, the adjustment of chord pitch has always been a technology that many guitar users cannot access, so it may finally be left to the shop owner or professional technician to handle. The purpos......

2022.10.31Published by @WCYRead More -

As we all know, the conductivity and thermal conductivity of aluminum shell is very good. It is second only to silver, copper and gold. Therefore, many industrial shells will choose various shells made of aluminum alloy. Its aluminum shell has high flexibility, and its depth can be cut arbitrarily. Usually, there is a circuit board slot inside. As long as the circuit board is inserted directly, it does not need to be fixed again. Its speed is incomparable to other types of shells. The quality of aluminum alloy shell is often relat......

2022.10.29Published by @WLPRead More -

The mechanical keyboard is loved by young people because of its excellent feel and quality. The mechanical keyboard has a longer service life than the ordinary membrane keyboard, which is about 10-20 years with proper maintenance. The mechanical keyboard is easy to realize the function of full keyboard keys without conflict. Mechanical keyboard has high playability. Of course, everything has two sides. Mechanical keyboards are expensive, waterproof and heavy. Although the mechanical keyboard has shortcomings, it does not prevent y......

2022.10.25Published by @WLPRead More -

When designing a part, it is best to think ahead of time about which process will be used to manufacture the model and optimize accordingly for that production process. Among them, the most common processing methods of plastic parts are CNC processing and injection molding. So how do we choose between these two processes? Plastic CNC VS Plastic Injection Molding CNC Machining CNC machining usually starts with a piece of material, and after several removals of the material, a set shape is obtained. CNC plastic processing is one of the main ways of making prototypes at present, mainly pro......

2022.10.24Published by @ZNRead More -

Because of their high security and convenience, smart locks have begun to enter the whole family and become the smart choice for many families. However, the residual fingerprints on the smart lock panel are a headache for users. Once the fingerprints remain, the panel will be dirty. It must be cleaned regularly, and secondly, leaving your fingerprints exposed will always make people feel unsafe. In response to this situation, some smart lock manufacturers have begun to use CNC engraving technology, which not only makes the locks more beautiful and elegant but also ensures that there is ......

2022.10.21Published by @ZNRead More