-

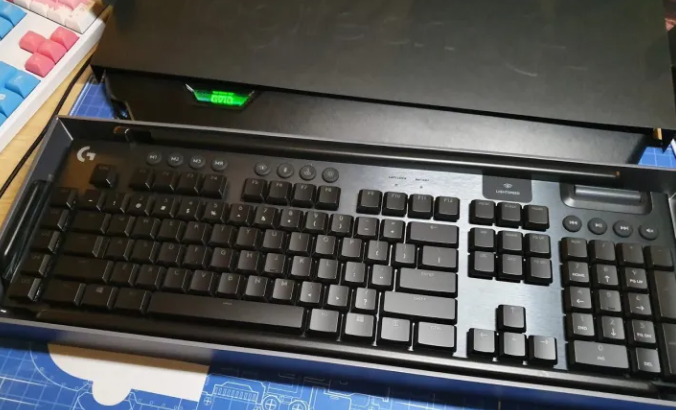

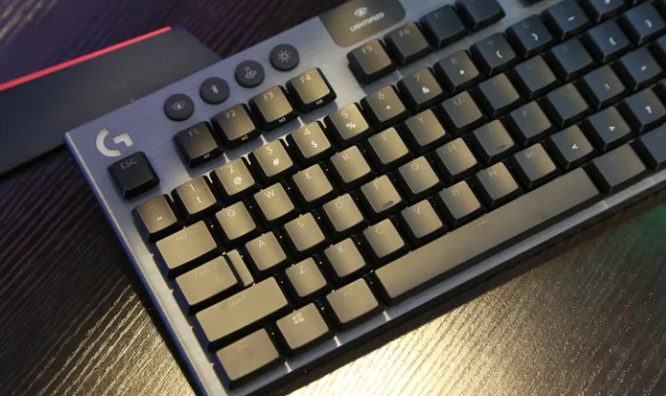

When it comes to gaming keyboards, Logitech has been a big name in the industry for many years. Their range of mechanical gaming keyboards features some of the most advanced technology available, including ultra-fast switches, customizable lighting, and programmable macros. In this article, we’ll be taking a look at two of Logitech’s top mechanical gaming keyboards: the Logitech G915 and the G815, and exploring the key differences between them. Logitech G815 Vs Logitech G915 for Mechanical Gaming Keyboard Design and Build Quality The Logitech G915 and G815 b......

2023.5.19Published by @WLPRead More -

When it comes to mechanical keyboards, people may come up with various silly and thick keyboard shapes, thick steel plates, exposed switches, and dazzling RGB light effects. None of them should be missing, otherwise it’s not a good idea to call yourself a game mechanical keyboard. Just tired Logitech felt that it was time to make a breakthrough, so G913 Lightspeed came out, a wireless game mechanical keyboard that truly integrated all the essence of Logitech’s keyboard design. And in the middle of this year, we saw a m......

2023.5.19Published by @WLPRead More -

If you’ve been looking into purchasing a new keyboard, you’ve most likely been familiar with the phrases “mechanical keyboard” and “regular keyboard.” Both of these types of keyboards have their advantages and disadvantages. However, what precisely differentiates these two kinds of keyboards from one another? What does CNC mean in keyboards? In the context of keyboards, CNC stands for Computer Numerical Control. CNC refers to the manufacturing process used to create keyboard cases or other components. It involves the use of computer-controlled machine......

2023.5.18Published by @ZNRead More -

As you experience more and more axes, you will eventually tend to choose “linear axes” because there are more usage scenarios for linear axes. When you are ready to replace the linear axis, you will find that you have entered another selection difficulty, because there are too many axes. How to Choose the Shaft Body of the Mechanical Keyboard Before 2014, the patent protection period of the cherry switch had not yet expired, and the mechanical switches on the market were basically cherry switches. It has been in existence for more than 30 years, and it can be said ......

2023.5.18Published by @ZNRead More -

When it comes to machining thermoplastic materials, two of the most common options are PVC and polycarbonate. Both materials have unique properties and characteristics that make them suitable for various applications. In this article, we’ll compare PVC machining vs. polycarbonate machining and discuss the key differences between them. Polycarbonate Vs PVC Machining PVC CNC MachiningPVC, or Polyvinyl Chloride, is a rigid plastic material that is widely used in construction, plumbing, and electrical applications. It’s easy to machine, making it a popular choice f......

2023.4.28Published by @WLPRead More -

When it comes to computer peripherals, keyboards are one of the most essential components. The right keyboard can significantly enhance your typing speed and accuracy, while also improving your overall productivity. While there are many different types of keyboards available, the two most popular types are membrane keyboards and mechanical keyboards. In this article, we will explore the differences between these two types of keyboards. Membrane Keyboard Vs Mechanical KeyboardMembrane Keyboard:A membrane keyboard is the most basic ......

2023.4.28Published by @WLPRead More -

Mechanical keyboards have become increasingly popular among gamers due to their tactile feel and durability. However, with so many options on the market, it can be difficult to determine which mechanical keyboard is the best fit for your gaming needs. In this article, we’ll explore some of the best mechanical keyboards for gaming 2023, taking into account factors such as switch type, customization options, and price. Best Gaming Mechanical Keyboards 2023Corsair K95 RGB Platinum XTThe Corsair K95 RGB Platinum XT is a top-of-t......

2023.4.28Published by @WLPRead More -

ASCII is a character encoding standard used to represent text in computers and other devices that use digital communication. The ASCII code of a keyboard is the specific set of numerical codes assigned to each key on a standard keyboard. In this article, we will explore the history of ASCII, how it relates to the keyboard, how it has evolved over time, and how to use the ASCII code for a keyboard. History of ASCIIThe history of ASCII dates back to the 1960s when the American Standards Association (ASA) created a committee to devel......

2023.4.28Published by @WLPRead More