Nails are an important fastener that is often seen in wood and other constructions. To find out the correct nail for specific uses, knowing its sizes is necessary. Here we introduce the parts and types of nails and the standard nail size chart to determine the diameter, gauge, and length.

What Is a Nail Fastener?

A nail fastener is a simple but essential tool used in woodworking, construction, and many other industries to join materials together securely. It is typically a slender piece of metal, often steel, with a sharp pointed end to penetrate materials and a flattened head on the opposite side to allow for hammering or driving. Nails work by creating friction inside the material along their shaft, holding pieces tightly together. They may be driven manually with a hammer or mechanically by a nail gun. Nails come in many shapes and sizes, designed for specific tasks, from general wood fastening to attaching roofing or concrete work. Their ease of use, strong holding power, and wide variety make them one of the most common fasteners in construction.

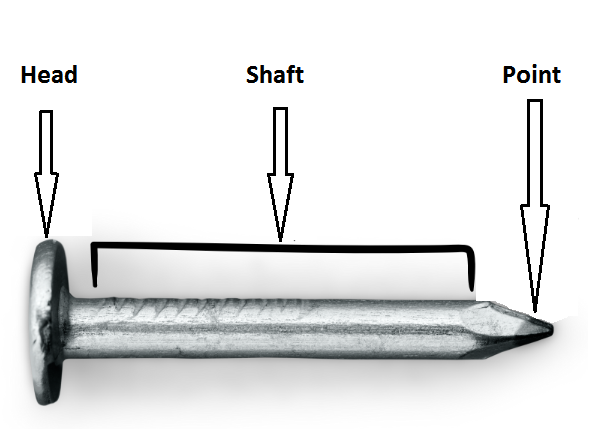

Parts or Components of a Nail

- Head: The head is the flattened or shaped top end of the nail that the hammer strikes. It provides a surface to drive the nail into materials and varies in size and shape depending on nail type and purpose.

- Shank: The shank is the long, narrow body of the nail between the head and the point. It is usually round but can be square or twisted and may have grooves or threads to increase holding power.

- Point: The point is the sharp end of the nail is designed to pierce the material easily. Points come in different shapes, such as round, diamond, or chisel, depending on the application.

Types of Nails

- Common Nails: These have a large, flat head and a thick shank, making them suitable for general construction, framing, and woodworking where strong holding power is needed.

- Box Nails: Similar to common nails but with a thinner shank, box nails are ideal for lighter woodworking tasks such as attaching thinner wood or making crates, offering less splitting risk.

- Casing Nails: These nails have a small conical head and a thin shaft, used for trim and molding where the nail head remains visible but subtle.

- Finishing Nails: With a very small, often barrel-shaped head, finishing nails are driven below the surface and covered with putty for a neat finish on cabinetry and interior paneling.

- Brad Nails: Tiny nails with very small or no heads, brads are used for delicate trim work and small woodworking projects.

- Concrete Nails: Hardened steel nails with grooved shanks and sharp points designed to be driven into concrete or masonry.

- Roofing Nails: These have very large, flat heads and short shafts to hold roofing materials like shingles effectively.

- Duplex or Scaffold Nails: Featuring two heads, one to drive and one to stop the nail from going flush, these are used in temporary structures for easy removal.

- Spiral or Screw Nails: These nails have a twisted shank that screws into the material for better grip and resistance to pullout.

Differences Between Nails and Screws

1. Shaft

One of the main differences between nails and screws lies in their design and how they are driven into materials. Nails have smooth shafts and are hammered or shot into place, relying on friction and shear strength to hold materials together. Screws, on the other hand, have threaded shafts that cut into the material as they are screwed in, which provides superior holding power and tensile strength.

2. Strength

Another key difference is in their strength under different stresses. Nails excel in shear strength, meaning they are better suited to withstand forces that push materials sideways against each other, like wind pressure on a house. They tend to bend rather than break under these forces. Screws offer higher tensile strength, which means they resist pulling forces better and are less likely to loosen when materials are pulled apart or bear weight.

3. Ease of Removal

Screws can be unscrewed easily with the right tool, making them ideal for temporary projects or applications where adjustments might be needed later. Nails are more difficult to remove because they are hammered in and often bend when pulled out.

4. Cost

Nails are generally cheaper and faster to install, especially when using nail guns or pneumatic nailers, making them popular for large-scale construction projects like framing or roofing. Screws require more time to install but provide tighter, more precise joints.

5. Visibility and Finish

Nails, especially finishing nails or brads, have smaller or less noticeable heads and are preferred for delicate trim and moldings where appearance is important. Screws have more visible heads but provide stronger fastening for cabinetry, decking, and structural joints.

Nails vs. Screws: Which One to Choose?

Choosing between nails and screws depends largely on the specific requirements of your project. If you need a fast, cost-effective solution for a large construction job like framing walls, roofing, or installing siding, nails are often the better choice. Their shear strength and flexibility allow them to handle lateral forces well, and pneumatic nailers speed up the process significantly.

For projects where holding power and strength under tension are critical—such as decking, cabinetry, or attaching hardware—screws are typically preferred. Their threaded design ensures a tighter grip and resistance to pull-out forces, which keeps joints secure over time. Screws are also easier to remove and adjust, making them ideal for temporary setups or projects that may require future modifications.

For finish carpentry and delicate woodwork, nails often win because their small heads are less visible and less likely to split wood. However, if the trim or molding requires strong holding power, trim screws with smaller heads can be a smart alternative.

Nail Dimensions Explained

- Penny Size (d): The penny size is a traditional measurement indicating the length of the nail. For example, a 10d nail is longer than an 8d nail. Historically, it related to the price per hundred nails, but now simply indicates size.

- Gauge: Gauge refers to the thickness or diameter of the nail’s shank. A higher gauge number means a thinner nail, so a 12-gauge nail is thinner than a 5-gauge nail.

- Shank Diameter: This is the actual thickness of the nail’s shaft measured in inches. Thicker shanks provide greater strength and holding power.

- Shank Length: The length of the nail measured from the bottom of the head to the tip, usually in inches. This determines how deeply the nail can penetrate the materials.

- Head Diameter: The size of the nail’s head, measured in inches. Larger heads offer more surface area to hold materials and distribute force, while smaller heads are used when a neater appearance is needed.

Nail Size Chart in Inches and MM (Diameter, Length, and Gauge)

| Penny Size | Length (inches) | Length (mm) | Gauge | Shank Diameter (in) | Head Diameter (in) |

|---|---|---|---|---|---|

| 1d | ¾” | 19mm | 15 | 0.072 | 5/32″ |

| 2d | 1″ | 25mm | 15 | 0.072 | 5/32″ |

| 3d | 1¼” | 32mm | 14 | 0.080 | 3/16″ |

| 4d | 1½” | 38mm | 12.5 | 0.098 | 1/4″ |

| 5d | 1¾” | 44mm | 12.5 | 0.098 | 1/4″ |

| 6d | 2″ | 51mm | 11.5 | 0.113 | 9/32″ |

| 8d | 2½” | 64mm | 10.25 | 0.131 | 5/16″ |

| 10d | 3″ | 76mm | 9 | 0.148 | 3/8″ |

| 12d | 3¼” | 83mm | 9 | 0.148 | 3/8″ |

| 16d | 3½” | 89mm | 8 | 0.162 | 7/16″ |

| 20d | 4″ | 102mm | 6 | 0.192 | 1/2″ |

| 30d | 4½” | 114mm | 5 | 0.207 | 9/16″ |

| 40d | 5″ | 127mm | 4 | 0.225 | 5/8″ |

| 50d | 5½” | 140mm | 3 | 0.244 | 11/16″ |

| 60d | 6″ | 152mm | 2 | 0.262 | 3/4″ |

| 70d | 7″ | 178mm | 1 | 0.283 | 13/16″ |

| 80d | 8″ | 203mm | 0 | 0.312 | 7/8″ |