When it comes to versatile metals, brass, copper, and bronze are three of the most widely used materials in industries ranging from construction and plumbing to art, electrical engineering, and marine applications. In this guide, we’ll break down the key differences between brass, copper, and bronze, exploring how their compositions, mechanical properties, applications, and costs influence where and why they are used.

What is Brass?

Brass is a versatile metal alloy primarily made from copper and zinc, with the proportions of each element varying to create different properties such as strength, hardness, and color. Known for its bright gold-like appearance, brass is resistant to corrosion, easy to machine, and has excellent acoustic qualities, making it popular for decorative items, musical instruments, fittings, and architectural applications. It also has antimicrobial properties and is widely used in plumbing, electrical connectors, and marine hardware. The combination of durability, workability, and aesthetic appeal makes brass one of the most important and widely used copper-based alloys.

Pros:

Attractive appearance: Brass has a bright gold-like color, making it popular for decorative items, jewelry, and architecture.

Corrosion resistance: It withstands water exposure well, making it suitable for plumbing, marine hardware, and outdoor fittings.

Workability: Brass is softer than steel and easy to cast, machine, and shape into precise components.

Acoustic properties: Its vibration and sound qualities make it the metal of choice for many musical instruments like trumpets and saxophones.

Antimicrobial surface: Like copper, brass naturally resists bacterial growth, which is beneficial in plumbing and healthcare applications.

Cons:

Lower strength: Brass is softer than bronze and steel, so it’s less suited for heavy-load or high-wear applications.

Susceptibility to dezincification: In certain environments, zinc can leach out of brass, weakening the metal and causing a porous structure.

Can tarnish: Brass darkens over time when exposed to air and moisture, requiring polishing if a shiny appearance is desired.

Moderate cost: While cheaper than pure copper, it is still more expensive than some alternatives like plastics or aluminum.

Lead content risk: Some brass alloys contain small amounts of lead to improve machinability, which may pose safety concerns in drinking water systems unless controlled.

Grades:

- Cartridge Brass

Common Grade: C26000

Composition: ~70% copper, 30% zinc.

Properties: Excellent ductility, easily cold-worked.

Applications: Ammunition casings, automotive parts, plumbing fittings. - Naval Brass

Common Grade: C46400

Composition: ~60% copper, 39% zinc, 1% tin.

Properties: High corrosion resistance, especially in seawater.

Applications: Marine hardware, propeller shafts, condenser plates. - Free-Cutting Brass (Leaded Brass)

Common Grade: C36000

Composition: ~61.5% copper, 35.5% zinc, 3% lead.

Properties: Excellent machinability, smooth finish, corrosion resistance.

Applications: Fasteners, valves, fittings, precision components. - Red Brass (Gunmetal Brass)

Common Grade: C23000

Composition: ~85% copper, 15% zinc.

Properties: Strong, highly corrosion resistant, reddish color.

Applications: Plumbing, architectural fittings, decorative uses. - Yellow Brass

Common Grade: C27000

Composition: ~65% copper, 35% zinc.

Properties: Bright golden color, good strength, easy to form.

Applications: Musical instruments, ornaments, household hardware. - Manganese Brass

Common Grade: C67300

Composition: Copper, zinc, plus manganese and iron.

Properties: Very strong, wear-resistant, better for heavy-duty mechanical use.

Applications: Gears, bearings, valve guides, industrial machinery.

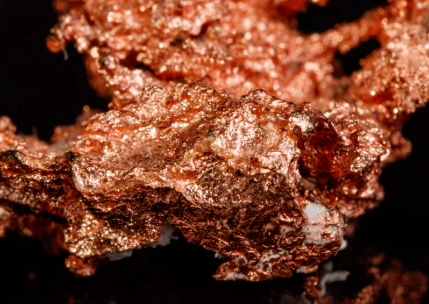

What is Copper?

Copper is a reddish-brown metallic element (chemical symbol Cu, atomic number 29) that is one of the earliest metals used by humans due to its excellent electrical and thermal conductivity, malleability, and resistance to corrosion. It is widely found in minerals such as chalcopyrite and malachite and is essential for modern industries, playing a critical role in electrical wiring, electronics, plumbing, and renewable energy technologies. Beyond industrial uses, copper is also a trace dietary mineral necessary for human health, contributing to the production of red blood cells and the proper functioning of the nervous and immune systems.

Pros:

Excellent conductivity: Copper is one of the best conductors of electricity and heat, making it essential for wiring, motors, and electronics.

Corrosion resistance: It forms a protective green patina (copper carbonate) over time, which helps prevent deeper corrosion.

Malleability and ductility: Copper can be easily shaped into wires, sheets, and pipes without losing strength.

Antimicrobial properties: It naturally kills bacteria and viruses, making it useful in healthcare surfaces and plumbing.

Recyclability: Copper can be reused indefinitely without losing quality, making it highly sustainable.

Cons:

High cost: Copper is more expensive compared to alternatives like aluminum or plastic.

Oxidation and tarnishing: While the patina protects it, some applications dislike the discoloration.

Softness: Pure copper is relatively soft and less durable under heavy mechanical stress compared to alloys like brass or bronze.

Weight: Copper is heavier than aluminum, which can limit its use in lightweight applications.

Theft risk: Due to its value, copper wiring and pipes are common targets for theft.

Grades:

- Electrolytic Tough Pitch (ETP) Copper – C11000

Purity: ~99.9% copper with small oxygen content (~0.02–0.04%).

Properties: Excellent electrical and thermal conductivity.

Applications: Electrical wiring, motors, transformers, busbars.

Note: Most common grade used worldwide. - Oxygen-Free High Conductivity (OFHC) Copper – C10200

Purity: 99.95% copper, no oxygen.

Properties: Superior conductivity, corrosion resistance, and ductility.

Applications: Vacuum systems, electronics, semiconductors, aerospace.

Note: More expensive than ETP. - Deoxidized Copper (DHP, DLP, etc.)

DHP (C12200 – Phosphorus-Deoxidized, High Residual Phosphorus):

Good corrosion resistance, used in plumbing and heat exchangers.

DLP (C12000 – Phosphorus-Deoxidized, Low Residual Phosphorus):

Better conductivity than DHP, but less than OFHC. - Alloyed Copper Grades

Arsenical Copper (C14200): Added arsenic improves corrosion resistance in marine environments.

Silver-Bearing Copper (C11300): Silver increases strength at high temperatures, used in power plants and furnaces.

What is Bronze?

Bronze is a durable metal alloy mainly composed of copper and tin, though small amounts of other elements like aluminum, phosphorus, or silicon may be added to enhance specific properties. Recognized for its reddish-brown color and resistance to corrosion, bronze was one of the first alloys ever created by humans, marking the beginning of the Bronze Age when it revolutionized tools, weapons, and art. Compared to pure copper, bronze is harder, stronger, and more wear-resistant, making it valuable for applications such as bearings, ship fittings, sculptures, coins, and musical instruments. Its strength, longevity, and historical significance have made bronze an enduring material throughout human civilization.

Pros:

High strength and durability: Bronze is harder and stronger than pure copper or brass, making it ideal for heavy-duty applications.

Corrosion resistance: It performs especially well in marine environments since it resists seawater corrosion and biofouling.

Low metal-on-metal friction: Bronze parts wear less when rubbing against other metals, which is why it’s commonly used in bearings, bushings, and gears.

Historical and artistic value: Its unique reddish-brown color and casting ability make it popular for sculptures, coins, and monuments.

Non-sparking: Bronze does not produce sparks when struck, making it safer in explosive or flammable environments.

Cons:

Higher cost: Bronze is more expensive than brass and sometimes even costlier than copper due to the addition of tin or other alloying elements.

Brittleness compared to pure copper: While harder, bronze can be less ductile, meaning it may crack under certain stresses instead of bending.

Weight: Bronze is relatively heavy, which can be a limitation in applications requiring lightweight materials.

Limited availability of tin: Since tin is less abundant, the supply and cost of bronze can fluctuate.

Oxidation: Although resistant to deep corrosion, bronze still develops a surface patina (often greenish or brownish) that may be undesirable for some uses.

Grades:

- Tin Bronze (Classical Bronze)

Common Grades: C90300 (Navy G Bronze), C90500 (Gun Metal), C90700

Composition: Copper + 5–12% tin.

Properties: Strong, wear-resistant, good corrosion resistance.

Applications: Bearings, bushings, gears, pump parts, marine hardware. - Phosphor Bronze

Common Grades: C51000, C54400

Composition: Copper + tin (3–12%) + small phosphorus.

Properties: Hard, tough, fatigue-resistant, low friction.

Applications: Springs, bolts, electrical connectors, bushings, musical instruments. - Aluminum Bronze

Common Grades: C95400, C95500, C95900

Composition: Copper + 5–12% aluminum, sometimes with iron or nickel.

Properties: Extremely strong, excellent wear and marine corrosion resistance.

Applications: Ship propellers, valves, heavy-duty bearings, aerospace parts. - Silicon Bronze

Common Grades: C65500, C66100

Composition: Copper + ~3% silicon + small manganese/zinc.

Properties: Strong, corrosion-resistant, good weldability, attractive color.

Applications: Marine hardware, sculptures, architectural fittings. - Manganese Bronze

Common Grades: C86300

Composition: Copper + zinc + manganese (technically a brass/bronze hybrid).

Properties: Very strong, wear-resistant, but less corrosion-resistant than tin/aluminum bronze.

Applications: Heavy-duty bearings, gears, industrial machinery.

Brass vs Copper vs Bronze, What’s the Difference?

| Aspect | Copper | Brass | Bronze |

|---|---|---|---|

| Price | Highest cost (pure metal, high demand) | Cheaper than copper (copper + zinc) | Often more expensive than brass, varies with tin content |

| Strength | Soft, malleable, not very strong | Stronger than copper, but softer than bronze | Strongest and most durable, excellent wear resistance |

| Applications | Electrical wiring, plumbing, roofing, electronics, cookware | Plumbing fixtures, musical instruments, decorative hardware, marine fittings | Bearings, gears, bushings, ship propellers, sculptures, coins |

| Color | Reddish-brown, develops green patina | Bright gold-like, can tarnish to dull brown | Reddish-brown to dark brown, develops deeper patina |

| Key Properties | Excellent electrical & thermal conductivity, antimicrobial, ductile | Attractive, corrosion-resistant, easy to machine, good acoustics | Hard, strong, wear-resistant, non-sparking, marine corrosion resistance |

- Copper = Best for conductivity (wiring, electronics).

- Brass = Best for appearance & workability (decor, instruments, fittings).

- Bronze = Best for strength & durability (marine, machinery, sculptures).