In mechanical design, making the right choices for bolt sizing, selection, and application is key for both safety and efficiency. Often, experienced engineers rely on thumb rules and practical experience for everyday applications. However, in situations where safety or dynamic loads are involved, precise bolt sizing calculations become necessary. This article provides a comprehensive overview of bolt preload, tension and shear load, bolt grades, and the calculation methods for bolt sizing, as well as practical thumb rules used in industry.

When to Calculate Bolt Size

Most design engineers do not calculate every bolt size for standard applications. For example, when designing a mounting bracket for a pneumatic cylinder, the cylinder often comes with a standard threaded hole for mounting. In such cases, using the specified bolt size or going one size up is sufficient, since the load on the bolt does not change much.

However, detailed calculations become necessary in certain situations. Mounting bolts for heavy hydraulic presses, where loads reach several tons, require careful calculation. Bolted joints in high-torque or high-speed drive lines also need precise sizing, especially when subjected to dynamic or vibrational loading. In these cases, it is the engineer’s duty to calculate bolt size, select the appropriate grade, and specify optimum preload.

Fundamentals of Bolting Connections

Bolting offers a non-destructive fastening method, allowing assembly and disassembly multiple times without damaging the components—unlike welding or riveting. Bolted connections can be made using a bolt and nut (through clearance holes), or a screw (bolted directly into a tapped hole).

The choice between bolting and screwing depends on the application. Bolting often requires free space around the nut, which can be challenging in compact assemblies. Screwing is more convenient in constrained spaces but is not suitable for thin materials where thread engagement is insufficient.

Recommended Thread Engagement

- Steel bolt in steel tapped hole or nut: Minimum engagement = 1 × bolt diameter

- Steel bolt in softer materials (aluminum, brass, cast iron): Engagement = 1.5–2 × bolt diameter

- Steel bolt in very soft materials (plastic, wood): Engagement = 2–3 × bolt diameter

Most of the load is carried by the first three to five threads. If thread engagement is too short, threads may strip before the bolt reaches its tensile capacity. Excessive engagement does not add strength but increases cost and material use.

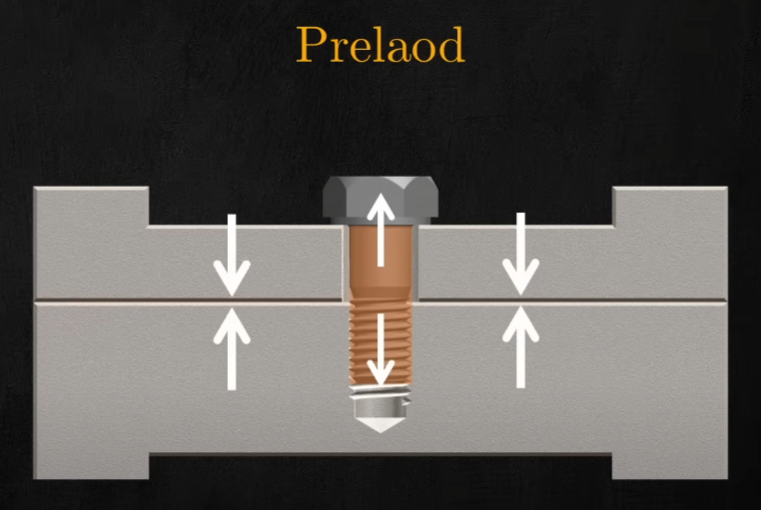

Bolt Preload – How a Bolted Joint Works

When tightening a bolt or screw, once the head or nut face contacts the component, further tightening stretches the bolt, putting it in tension, and compresses the jointed parts. This creates a clamping force that locks the assembly together by friction.

If insufficient preload is applied, the joint remains loose and can easily separate under load. Proper preload ensures that even under vibration or impact, the bolt doesn’t experience direct cyclic stress, which helps avoid fatigue failure.

Bolt Preload Calculation

The recommended preload is about 70% of the bolt’s yield strength:

Preload Force = 0.7 × Yield Strength × Tensile Stress Area

Example:

For an M10 bolt, grade 8.8 (yield strength 640 MPa), the weakest cross-section is at the threads. Calculating the area and applying the 70% rule gives a preload of about 26 kN. Tightening torque can then be estimated, although the torque method is only accurate to ±25%. In highly demanding applications, direct measurement of bolt elongation is preferred.

Shear Load and Tension Load in Bolts

The load on a bolt can be either tensile (along the axis) or shear (perpendicular to the axis).

- Tensile Load: The bolt resists forces pulling the joint apart.

- Shear Load: The bolt resists sliding forces between jointed parts.

Preload not only locks the joint but also increases its ability to resist shear loads through friction between the parts. For example, a preload of 26 kN with a friction coefficient of 0.3 can resist about 800 kgf of shear before sliding occurs. If the external shear is less than this, it is absorbed by the joint surfaces and does not reach the bolt.

The Role of Washers

Washers do not increase the load capacity of a bolt but serve to:

- Distribute load: Increase contact area, reduce surface pressure—particularly important for soft joint materials.

- Protect surfaces: Prevent wear or galling during tightening.

- Improve frictional locking: Provide a smoother, larger contact area, improving resistance to loosening under vibration.

Thus, washers make joints more reliable and durable by distributing loads, protecting surfaces, and enhancing friction, but they do not affect the bolt’s actual strength.

Bolt Sizing Calculations

To determine the correct bolt diameter for a given load, consider:

- Proper preload

- Sufficient thread depth

- Use of washers

A bolted joint fails when the applied load exceeds the bolt’s yield strength (not just the ultimate tensile strength), as permanent stretching results in loss of preload and joint loosening.

Calculation Steps

- Required Area:

Area (A) = Applied Force / Allowable Stress (use yield strength) - Type of Loading:

- For tensile loading, use tensile yield strength.

- For shear loading, use shear yield strength (about 0.58 × tensile yield strength for steel).

- Factor of Safety:

Adjust stress values by an appropriate factor of safety depending on the application:- Static joints: 1.25–2

- Variable loads: 2–3

- Cyclic or fatigue-sensitive: 3–6

- Safety-critical: 4–8

- Number of Bolts:

Distribute the total required area among all bolts used:Area per bolt = Total Required Area / Number of Bolts - Bolt Diameter:

Solve for diameter:d = sqrt( (4 × Area) / π )

Example: Tensile Load

Attaching a hook to a wheel loader for a 20-ton load:

- 20,000 kg × 9.81 = 196,200 N

- Select grade 8.8 (yield strength 640 MPa), factor of safety 3

- Required area: 919.68 mm²

- Using four bolts: 229.9 mm² per bolt

- Calculated minor diameter: 17.1 mm (M18 or safer, M20)

Example: Shear Load with Dynamic Effects

Designing a cardan shaft flange to transmit 0.8 kNm torque at 10,000 rpm:

- Calculate static and dynamic shear forces based on torque, radius, and inertia.

- Use grade 8.8, shear yield strength 371 MPa, factor of safety 5.

- Required area: 188.8 mm²

- Using M8 bolts (area 36.6 mm²), need at least 6 bolts.

Bolt Grades and Standards

Bolts are classified by strength grades, defined by international standards:

- ISO Metric Grades (e.g., 8.8, 10.9, 12.9):

- First number × 100 = minimum tensile strength (MPa)

- First × second number × 10 = minimum yield strength (MPa)

- Other Standards:

- SAE, ASTM, and JIS use different numbering systems but the principle is similar.

Grade Selection:

- Below 8.8: Low carbon steel, low strength, used for light duty.

- 8.8: Medium carbon steel, quenched and tempered—commonly used in machinery.

- 10.9 and above: Alloy steel, high strength, used in high load or vibration applications.

- Stainless steel: Grades A2-70 (700 MPa) and A4-80 (800 MPa) are common in environments requiring corrosion resistance.

Practical Thumb Rules for Bolt Sizing

In non-critical cases, simple rules can speed up the design process:

- No or Compression Load Only:

If bolts are only locating and not loaded, select a size that fits and looks appropriate. - Thread Engagement:

- Steel plates: Engagement = 1 × bolt diameter.

- Aluminum: 1.5–2 × bolt diameter.

- Quick Load Estimation:

- M6 bolt (grade 8.8): ~1 ton tensile load

- M10 bolt (grade 8.8): ~3 tons tensile load

- Sheet Metal:

- Thickness <2 mm: Avoid threading; use weld nuts or through bolts with nuts.

- Thickness ≥3 mm: Make threads, ensuring at least 3–4 engaged threads.

Remember, bolt sizing calculations serve to prevent failure in demanding applications, not to minimize cost. For lightly loaded or non-critical joints, select a bolt size that fits well and use your engineering judgment.